There are various levels of sophistication that we can apply to develop pig feed specifications. Comprehensive pig growth models can be useful, particularly when setting up feed specifications for the first time, or when there is a major change to economic or physical data.

However, these can be very time consuming, need to be run by a nutritionist, and often the input data is not available. There is consequently a requirement for simpler “rules of thumb” that can be used on a day-to-day basis when advising pig producers and formulating feeds.

Growth, feed conversion

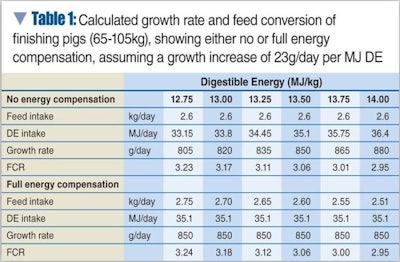

A simple starting point is to estimate growth and feed conversion, across a range of energy concentrations, and from this determine feed cost/kg gain. An example is given for pigs from 65-105kg live-weight using a growth response of 23g gain/MJ DE as shown in Table 1. In this example, the degree of energy compensation has little influence on feed conversion at a particular energy concentration.

In order to examine the economics of energy density, two series of feeds have been formulated using differing raw material cost-sets. In the first, as shown in Table 2, barley is £7/t less expensive and wheat feed £15/t less expensive, than wheat. Extracted rape meal is £100/t less expensive than soya meal, and soya oil is £850/t. These price differentials are typical of those in the UK in 2010.

Increasing energy density initially leads to a replacement of wheat feed by barley and then the barley by wheat. At higher energy levels rape seed meal is replaced by soya bean meal and fat addition is increased. In this example, using the feed conversation calculated in Table 1, feed cost per kg live weight gain is minimized at around 13.6 MJ DE/kg, irrespective of the degree of energy compensation.

Energy unit cost shows that at 12.75 MJ DE/kg there is no cost to energy (see Table 3), as it is “floating” above the minimum, but the cost increases to almost £27/MJ DE in the feed with the highest energy density, when the additional energy is from expensive soya oil. Previously it has been estimated that feed cost/kg live weight was minimized at around 13.6 MJ DE/kg. At this energy concentration the unit cost of energy is about £11.51/MJ (Table 3); this is the value of DE and can be used on a routine basis as a simple check when formulating feeds.

In other words if, having formulated a feed, the unit cost of energy is say £5/MJ DE then there are savings in feed costs by using a higher energy feed. The value of energy determined in this example is specific to this specification and the costs used, and assume that amino acid intake is not limiting. In situations where pigs are not showing energy compensation, feed intake and amino acid intake remain constant, and so the use of energy unit cost is valid as it is only energy under consideration.

However, where energy compensation is evident, feed intake and thus amino acid intake will fall with increasing energy concentration, and energy unit cost will be less accurate, as it is not only energy intake that is changing but also that of amino acids.