This winter, producers are going to have to fight the impulse to reduce ventilation rates and/or lower brooding temperatures. While these actions may save a few hundred dollars on gas usage, more money will be lost in the form of missing revenue due to poor body weight gains and feed conversion.

Instead of sacrificing performance, efforts should be made to reduce gas usage while at the same time improving the environment for the birds. Many things that improve energy efficiency also result in better house environments.

Here are some steps that can be utilized in the cold weather months to reduce fuel usage to heat poultry houses while at the same time improving environmental conditions to optimize broiler performance.

Close curtains tightly

While the trend in new broiler housing is to build solid side walls, there are still a lot of curtain sided houses throughout the poultry industry. Insulation value of curtains is a definite problem, but loose fitting curtains can be a significantly bigger issue.

The key to minimizing heat loss and reducing fuel usage in these houses is to tightly close the curtains. This can be accomplished through a few simple steps: Make sure the curtain is tall enough to extend past the curtain opening by at least six inches.

Be observant of where the pulleys are placed. Pulleys need to be within one inch of the top of the curtain opening with no metal siding ribs between them, otherwise the curtain will be held away from the side wall.

Check the seal along both the top and bottom of the curtain. The wood strip placed along the bottom of the curtain should be secured tightly.

The top of the curtain should pull up into a curtain pocket that is sealed tightly. Loose curtain pockets can result in an excessive amount of heat loss.

Totally enclose the house

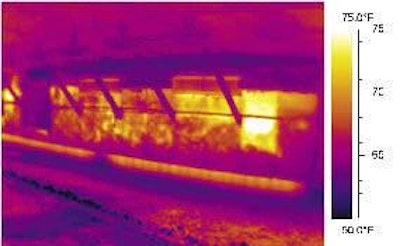

Leaky or loose housing is a big deterrent to both efficient energy use and good bird environments. When the fans are off, cold air will seep through these cracks and holes reducing the air temperature and result in poor litter quality. When the fans are on, the air will take the path of least resistance to enter the house. Instead of coming through the desired air inlets, it will come in through the cracks and holes, reducing litter quality and negatively affecting overall air quality. In addition, houses with curtains with very low insulation value lose more heat.

Producers with curtain-sided houses should consider converting them to solid side wall buildings. In doing so, less heat will be lost through the side wall of the house. Not only will this improve the side wall insulation, but it generally results in a tighter house. Closing in the side walls can provide up to 30 percent fuel savings.

There are several methods to enclose solid side walls, which include, but are not limited to, using insulation and plywood, polyurethane foam or Thermall. Producers interested in enclosing the side walls should investigate their options in terms of installation, material costs and longevity of the material in broiler house environments.

A significant part of reducing heat loss is to tighten up the house. Static pressure tests should be conducted annually by turning on two 36-inch fans with the vents closed. Static pressures of 0.15 to 0.18 are acceptable but static pressure above 2.0 is preferable.

Install circulation fans

Installing circulation fans will improve air movement in the house and break up the heat stratification that forms when hot air rises to the ceiling. Circulation fans will move the warm air at the ceiling down to the floor to heat and dry the litter. Circulation fans have demonstrated fuel savings of as much as 10 to 15 percent.

It is better to use smaller circulation fans (18 to 20 inches) with small horsepower motors so they can be run continuously. This will keep the environment more uniform than running fans a few seconds at a time.

Control ammonia

The largest source of heat loss in a broiler house is through the ventilation system. Ventilation is needed to bring fresh air into the house to maintain good air quality and to keep the floors dry. Litter amendments are a method of maintaining good air quality without over ventilating.

Litter amendments should be applied prior to chick placement following the directions of the manufacturer to ensure optimum performance and product life.

Minimum ventilation rates should be adjusted to keep ammonia concentration low and to maintain relative humidity between 50 and 70 percent. If relative humidity becomes greater than 70 percent, minimum ventilation should be increased to prevent the floor from becoming too wet. Drier floors will reduce ammonia production and minimize the ventilation needed to maintain good air quality.

Darkling beetles and pest management

Once a house is constructed and tightened to an acceptable level, efforts should be made to maintain it as such.

Darkling beetles can actually contribute to poor ventilation efficiency. Beetle larvae will burrow into the insulation to pupate, creating gaps and holes in the insulation, and reducing or destroying the R-value. Darkling beetle control is a constant battle and persistence is required. Be sure to use an approved product for darkling beetle control, and apply it strictly according to the manufacturer's guidelines. Beetles can develop resistance to insecticides over time which will necessitate that products be rotated on a routine basis.

Consider installing attic inlets

Attic air is typically warmer than outside air on cold days. By installing attic inlets, producers can capitalize on solar heat trapped in their attics and ventilate houses more during the day. Average houses with attic inlets are capable of being ventilated 20 percent more than houses without attic inlets on cold days without experiencing the 20 percent increase in fuel usage that one might expect. In studies conducted in Georgia, producers experienced between 10 and 20 percent lower fuel usage compared to houses without attic inlets.

Houses with attic inlets tend to be less drafty as the air from the attic is warmer than the air from outside. This means houses will have better moisture control, drier litter and better air quality, and all this adds up to better bird performance.

Attic inlets will be more effective in houses that can pull 0.13 inches during a static pressure test. Lower static pressures suggest that more air will enter through cracks than through the inlets.

Cold weather management of broilers and turkeys is a challenge for many producers. Rising costs of fuel complicate the issue even more.

The key is to choose ways to reduce fuel usage that do not have negative impacts on bird performance.