Cargill UK is investing GBP35 million (US$56.3 million) in its main poultry processing plant to make it one of the most efficient in Europe. Using the latest technology, the Herefordshire site will build a new chiller and expand the current hatchery.

The work will take place over the next three years and will increase the number of birds being processed from 1.6 million a week to 2 million as the company keeps pace with the UK's increasing demand for home-produced poultry.

Efficient and competitive

Cargill has already installed a controlled-atmosphere stunning chamber and an upgraded reception area at its Hereford plant at a cost of GBP4 million. Work on the new hatchery and chiller is due to start next, although planning permission for the chiller still awaits approval. Cargill anticipates that, once approval is gained, the chiller will be finished by the end of 2014.

Disruption to production schedules will be kept to a minimum as the chiller will be erected alongside the plant. More upgrades will follow to complete the investment and increase efficiency at the plant.

Managing director of Cargill Meats Europe, Pilar Cruz, explains: "This is an exciting time for the poultry industry, and as demand for fresh chicken grown in the UK continues to rise among retailers and consumers, we aim to position ourselves to better support this. This investment will position Cargill for future growth and strengthen our relationship with key strategic customers in the UK."

Working with farmers

Cruz adds: "Cargill's investment plans will not only help us support our customers but also local farmers and the industry as a whole. We are committed to working together with our farmers, customers, suppliers and communities to help the UK poultry industry to thrive and to leverage our broad global knowledge, ethics and values to build strong sustainable growth in the UK."

The company's expansion plans come at a time when the horsemeat scandal is still on the minds of many consumers, and traceability is increasingly important as more and more people opt to buy British.

According to one recent report by the British Poultry Council, poultry meat is predicted to make up half of all UK meat consumption in 2014. This figure represents an increase of around a third in 20 years.

Building strong business relationships

Since the horsemeat scandal, the company has found that its customers are looking for reassurance about food sources and the supply chains they use, and Cargill has been able to provide this assurance. It first started working in the UK in 1955 and has long-established relationships with chicken farmers in Herefordshire, some of which have lasted more than 50 years. All the birds the company processes are from the UK and include the standard fast-growing, high-meat yielding breeds of Ross, Hubbard and Cobb.

Homegrown chickens

This latest investment in the UK demonstrates Cargill's commitment to building a sustainable long-term business supplying homegrown chickens. Cargill works with 120 farms and provides them with feed and chicks from their own company facilities as part of a vertically integrated business. The farmers send the chickens back to Cargill at 35-56 days old for processing.

As part of this commitment, Cargill spoke to farmers about the expansion plans before they were implemented and has increased supplies available to farmers to enable them to provide more birds for processing as (and when) they are needed.

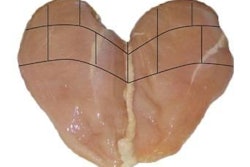

UK chicken producers have not had the benefit of subsidies; they have had to be resourceful and find more efficient ways to work, such as owning the supply chain and producing food that people really want to buy. Among the produce Cargill supplies to leading retailers and customers are tray-packed fresh chicken and portions, barbecue chicken products, rotisserie and marinated chicken, and coated chicken products. All the prime cuts of chicken are used in the UK, but some of the dark meat and by-products are exported.

The number of employees is expected to rise as new direct and indirect roles are created as a result of the latest investment. But it is not yet known precisely how many more employees will be needed in addition to the 2,000 already working at the Hereford plant. Cargill also has a smaller poultry plant at Newent, Gloucestershire, that has 1,000 employees.

Poultry welfare

Cargill also carefully monitors animal welfare at its Hereford plant. All birds are sourced, reared and processed to Red Tractor Farm Assurance standards, guaranteeing that they have been cared for responsibly from breeding to processing and are fully traceable back to independently inspected farms. In addition, the chickens have access to natural daylight and enriched environments to provide stimulation for the birds during the rearing process.

All employees who work with live birds during the production process are given specific training to ensure that welfare procedures and requirements are complied with. This includes the processing line being supervised by an independent Official Veterinary Surgeon (OVS) who, as well as checking hygiene and quality standards, independently monitors bird welfare at every stage. The OVS supervises the official health and welfare checks of all live birds entering the plant, the stunning and slaughter process, and the hygiene and food safety inspections .

Cargill's continuing commitment to welfare, innovation and efficiency will set it in good stead for the future. As the new plant comes into operation, it will put the company in a strong position as one of the main suppliers of the 2.2 million chickens Britons consume daily.