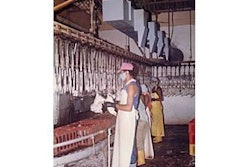

Despite alternatives, electric stunning remains the most common approach at the poultry processing plant to render birds unconscious.

Given its widespread use, it is worth considering whether the electric stun bath is being used properly, where things can go wrong and what adjustments can be made to prevent or remedy problems.

When stunning is not properly performed, the quality of processed chickens will be reduced, and the number of condemned birds will increase. Yet measures to ensure efficient and correct stunning are often overlooked. It could be the case that plant managers are unaware of what needs to be done, or it could be the case that there are concerns over the difficulties or expense of making these adjustments.

There are 10 important points along the stunning process that can be checked to ensure that the number of condemned birds is kept to a minimum.

1. Darkening the hanging area

When chickens arrive at the processing plant and are hung onto shackles, they must be handled correctly, and their stress levels must be kept as low as possible. To facilitate this, the receiving area should have a reduced light level.

Many plants use blue light, although red and green light are also used in some plants. Chickens do not see light from the ultraviolet spectrum, and when in a darkened environment, they will be more relaxed and may even sleep.

2. Fill all the shackles

It is important to ensure that each and every shackle on the overhead conveyor is hung with a bird - there should be no gaps.

When gaps on the shackles do occur, fewer birds will enter the stunning bath than planned. This means that those who do will receive an electric current that is higher than planned, which can result in damage to the carcass.

It is not simply empty shackles that can lead to problems. Each bird must be hung properly, or quality and efficiency will be affected.

Additionally, it is worth remembering that in addition to affecting the quality of the processed bird, gaps on the conveyor can lengthen to time needed to process a batch. In some cases, this can result in staff having to work additional hours.

3. Breast comforter

It is important that chickens are kept as calm as possible on the way to the stunner.

The chicken's breast contains a high concentration of nerve endings, and physical contact with this part of the bird via the breast comforter, encourages relaxation and consequently extension of the neck.

However, breast comforters should not be made of metal, because if the birds flap their wings on the way to the stun bath, they could hit the comforter. Violent contact with a hard surface can result in hematomas.

An agitated bird that struggles and flaps its wings will pump more blood into its breast muscles and wings. When the carcass is bled, it may not be possible to drain all of this additional blood ,and this will impact the quality of the processed carcass.

4. From the last hanger to the stunner entrance

Passage from the last hanger to the stunner entrance should take no more than 20 seconds to prevent too much blood from flowing into the wings and neck under the force of gravity. If blood does accumulate in these areas, it cannot be fully drained during bleeding.

5. Pre-shock

If the above measures have been implemented correctly and the current in the bath has been properly adjusted, birds should enter the stunning bath in the correct state.

There are two commonly employed ways in which birds enter the stun bath.

One is similar to the way in which birds enter the scalder. This is the most recommended approach, because the birds enter the bath in a relaxed state, and their heads are at a right angle to the water.

The other way is to slide them along a ramp. However, in most cases this ramp becomes damp, because when birds enter the stun bath, they can flap their wings, which splashes water back onto the ramp. Should those birds following behind flap their wings and come into contact with the damp ramp, they will attract the electric current. This can result in a contraction of the neck and encourages further flapping. These birds may pass above the stun bath rather than through it, meaning that they remain in a state of consciousness.

Should this occur, there will be an impact on the quality of slaughter and bleeding and an increase in hematomas, as birds will struggle violently in the shackles.

Because of these drawbacks, there is a second isolated ramp in some plants.

6. Depth of stun bath water level

Stunning starts when the chicken's head touches the metal grill that lies two inches below the surface of the water in the bath. The electric current enters the skull, continues to the brain and passes through the muscles and soft tissues until exiting via the legs.

However, should the grill be positioned more deeply than two inches below the water's surface, then the water will cover part of the neck and on some occasions the top of the breast. Should this be the case, muscle contractions can occur, which will affect meat quality.

7. Automatic current adjustment

When some shackles are empty, birds entering the water will receive a greater charge of electricity than is desirable.

There are ways to overcome this problem, and equipment is available that senses the number of birds in the water and adjusts the amperes accordingly.

8. Special ramp

In those processing plants where it is not possible to modify the entrance and exit routes of the stunner, an isolated plastic ramp can be installed with a length and slope that prevents it from becoming damp, which removes the risk of pre-shock.

9. Plastic pipe at the stunner exit

Occasionally, when the stunning process is not properly controlled, birds may exit the bath shaking. A length of plastic pipe can be installed at breast height where the birds exit the bath to counteract this shaking and ease access of entry of the automatic killer.

10. Monitor the current

A consequence of excess current can be that the chickens' wing veins become dilated. Similarly, the femoral vein in the leg can take on a bluish appearance if the current is incorrect.

To achieve correct stunning requires that a series of variables need to be properly monitored. Paying attention to these can help to reduce the number of condemned birds, and maintain the highest possible yield post stunning.