At a time when feed ingredients are at an all-time high, pig producers and feed manufacturers can make practical use of feed enzyme technology, matching inclusion rates with cereal grain feeding values. By more accurately reformulating the feed with enzymes, feed costs can be reduced by around €4/tonne, at current prices. A new service from Danisco Animal Nutrition represents one tool to help do just that.

Differences in wheat varieties, climatic growing conditions, soil types and agronomic inputs are some of the factors which contribute to wheat variability. Variations in wheat feeding value, resulting in variable pig performance, can cost the producer in excess of 1.50 per pig in reduced net margin.

Research from the UK, Denmark and Australia clearly illustrates the problem of wheat variability on pig performance. In a trial conducted in the UK, six wheat varieties were grown on the same plot of land and incorporated into otherwise identical pig diets. There was an 18 percent variation in pig daily gain between the best and the worst wheats, with differences in feed conversion ratios (FCR) ranging from 1.28 to 1.47. Pig performance was even more variable in similar trials conducted in Australia and Denmark, with variations in growth rates of 30 percent or more.

Reducing variability

Different types of fibre within wheat and other grains such as barley, rye and triticale, affect their feeding value. Soluble fibres in the cereal grain dissolve in the pig's gut, forming viscous gels which trap nutrients, and slow the rate of digestion and the passage of feed through the gut. Insoluble fibres can also hold water and bind water-soluble nutrients, as well as enclosing them so that they are less available for digestion. Both types of fibre create more bulk in the pig's gut, which can reduce feed intake and subsequent growth.

Optimising enzyme use

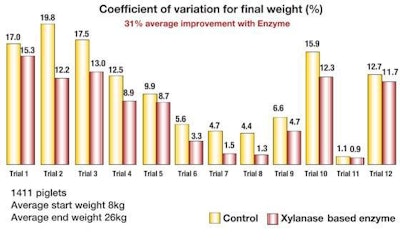

The contribution that enzymes can make at all stages of pig production, from weaners to finishers, has been consistently demonstrated. Adding xylanase-based feed enzyme systems has been proven to increase nutrient availability and reduce variability in the feeding value of key cereal grains. These enzymes break down the anti-nutritive fibres, resulting in more consistent diet performance, increased daily gain, improved feed efficiency and more uniform pigs. For example, an average of 22 trials with grower/finisher pigs fed wheat-based diets showed that adding a feed enzyme improved daily gain by more than 5 percent and feed conversion by 4.5 percent . Across 11 trials, enzyme addition to wheat-based diets also improved pig weight uniformity by, on average, 27 percent (Figure 1).

Feed manufacturers and pig producers using feed enzymes have the option of either reducing feed costs by adjusting dietary nutrient specifications to maintain pig growth and FCR, or of increasing overall pig performance by adding feed enzymes to an existing formulation.

The magnitude of response to enzyme addition largely depends upon the fibre characteristics of the grain. Some wheats, for example, are more responsive to enzyme addition than others, and this is the basis for Danisco's new Porcheck service. The service combines a measurement of the grain's response to enzymes with a unique software program to calculate the most cost-effective dose of Porzyme.

Economic benefits

The basis of the software program and related service is a series of 20 response trials that measured daily gain and FCR effects with varying Porzyme addition. In developing the model, 142 wheat samples from across Europe, Canada and Australia were analyzed to identify which factors had most relevance to the response to Porzyme addition. The parameters measured included dry matter, crude protein, lysine, oil, starch, ash, calcium, phosphorus, potassium, gross energy, near infrared reflectance (NIR) digestible energy (DE), crude fibre, hemicellulose, neutral detergent fibre, soluble and insoluble non-starch polysaccharides, phytate phosphorus, lignin, non-starch available carbohydrates and viscosity.

The wheat samples were then formulated into diets with varying levels of enzyme addition and fed to either young pigs or grower/finisher pigs. A complex set of analyses identified certain fibre fractions as being the key factors in wheat and other grains which determine the magnitude of the enzyme response. By measuring these key factors in cereal grains, it is possible to determine the optimum dose of enzyme to maximise profit.

The financial benefits of using feed enzymes will depend upon relative raw material prices and, particularly, the cost of energy in the ration. There has never been a better opportunity to reap the benefits from enzyme addition.

Data generated from the Porcheck optimization system, used in conjunction with least cost feed formulation, demonstrates currently that net savings in feed costs ranging from 1.3 percent to 2.0 percent can be made from the use of specific Porzyme in diets containing low' and high' responding wheat respectively.

This new service offers pig producers and feed manufacturers the opportunity to confidently exploit feed enzyme technology and to help minimize feed costs and improve growth uniformity at a particularly challenging time for the pig industry.

.jpg?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)