Responding to growing demand for novel products, with low production costs that still deliver financial gains to producers and retailers and satisfy consumers, has been a major factor in successfully launching various consumer goods.

And the food industry is no exception.

The poultry industry, a core part of food production, has grown by leaps and bounds around the world. In Asia, growth has been particularly strong in China and India. The latter is now the third-largest egg producer in the world, with the sector recording growth rates of 6-7% annually. Per capita egg consumption, which stands at some 40-50 per annum, is forecast to reach 180 a year by 2015.

Rising levels of disposable income among Indian consumers, a desire for added value and quality, increasing levels of health consciousness, changing dietary habits and an awareness of quality have all stimulated the marketing of clean and wholesome table eggs. This, in turn, has given momentum to the processing and marketing of value-added eggs and egg products, and these products are expected to continue growing in popularity.

Adding value

Value-added eggs are not a new concept, and adding value to eggs has, in fact, been practiced for centuries. Tea eggs, century eggs and now designer and lutein-enhanced eggs and organic eggs are examples of how value has been added to a basic product.

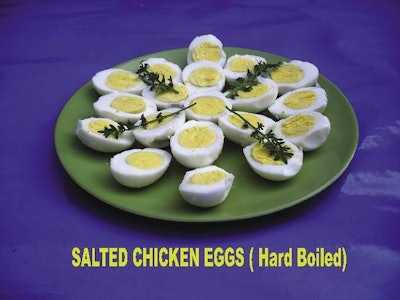

Preparation of salted eggs is one way of producing a convenient food product with an extended shelf life. Salting of eggs not only results in a tasty and convenient food but also offers ease of serving to retailers as well as to consumers.

While in some parts of the world, the salting of duck eggs is practiced, processing and marketing of salted eggs is yet to become established in India, or in many other markets, meaning that potential commercial gains from the practice are not being taken up.

While processing and marketing of salted eggs may be held back by the lack of knowledge of a standard methodology that overcomes the problem of salt penetration of the egg contents, this does not mean that the market for salted eggs is not without potential.

On careful examination, it can be seen that there are many ways to overcome these problems to ensure that salted hard-boiled eggs are a good end product.

Any process for preparing salted eggs in India needs to be simple so that it can be carried out by unskilled workers or housekeepers.

Another problem facing commercialisation of salted eggs is that there is no substantial scientific data on storage quality.

Minimal investment

In view of this lack of information, extensive studies were carried out at the Central Avian Research Institute, Izatnagar, to standardise a technique for the salting of chicken table eggs. Attention was also paid to ensure that any technology would work with a minimum of additional investment, a requirement that would help to ensure strengthening of rural entrepreneurship and that would additionally work where there were no electricity supplies.

Studies have shown that dipping chicken table eggs in commercial synthetic vinegar followed by their treatment with a saturated solution of common salt for set periods results in tasty and highly acceptable salted eggs.

Significant losses in egg weight of salted and unsalted control eggs were recorded during their prolonged storage at ambient (27-37C, RH 32-42%) as well as refrigerated (4±1C, RH 80-85%) temperatures, for up to 15 days. However, salted eggs stored at room temperature were less affected than unsalted eggs.

Similarly, the increase in pH of salted egg albumen during extended storage of eggs was significantly less when compared with the unsalted eggs. Internal egg quality parameters including albumen index, yolk index and Haugh unit score for salted eggs were also found to be significantly superior to those of the unsalted chicken eggs at all stages of storage.

Unsalted eggs stored at room temperature retained good quality only up to five days while those that had been salted lasted for seven. The protein profile, determined through SDS-PAGE, showed the presence of "Avidin" band in all the freshly salted as well as the unsalted eggs. However, Avidin band could be observed only in the albumen samples from salted eggs stored for five days under refrigerated temperature. This showed that the nutritive quality of salted eggs could be better preserved in comparison with unsalted eggs.

Lower microbial loads

Salted eggs had significantly lower microbial loads (total plate counts, anaerobes, yeast and moulds), than the unsalted groups. Coliforms and Staphylococci were not present in the experimental eggs at any stage of processing and storage. In view of the high microbial counts and undesirable quality in the samples stored beyond 10 days, the studies were not confirmed for longer periods.

Sensory evaluations also confirmed the above mentioned trends, indicating superior scores for the salted eggs even when stored at ambient or refrigerated temperatures for seven and 10 days, respectively, against five and 10 days for unsalted control eggs.

Human energy (HE) requirments for processing salted chicken eggs, at laboratory scale, was determined at 25.84 paisa per egg. It was concluded from the studies that salted chicken eggs could be safely consumed for up to seven to 10 days of ambient (27-37C, RH 32-42%) and refrigerated (4±1C, RH 80-85%) storage, respectively.

Depending on the marketing structure, the monetary gains per egg could range from 20-50%.