Different markets and different environments bring different choices. The clearest illustration of this effect in pig production is the way in which the regions of the world differ for the type of terminal sire they favour. For example, the market in North America seems to prefer mostly the Duroc, while a large part of Europe focuses on terminal boars of Pietrain and Yorkshire derivation.

Sometimes the choice has been determined by nature of the feed used. Some ingredients require animals in the slaughter generation to have a higher intake capacity. Duroc-derived market hogs tend to perform relatively well under those circumstances, which may be the most important reason behind producers in North America choosing the Duroc or products based on Duroc genes.

Processing plant requirements also have their influence on the choice of terminal sire. Ultimately every producer wants to have the maximum proportion of finishing pigs within the grid of carcase measurements receiving the highest price from the processor. However, the preferred carcase description as defined by the penalties imposed for sub-optimal weight, fat depth and loin depth is difficult to achieve when the variance in the population is large. Both the producer and the processor would gain if pigs could be grown in homogeneous groups to a specific end point rather than requiring extensive sorting at slaughter.

Causes of variation

Unfortunately, variance has a tendency to increase throughout the production cycle. Actions to limit it should therefore start by aiming to minimise initial differences. Various nutritional and management strategies for both dry and lactating sows can be implemented to promote this. Also, since a key component in achieving steady growth rates is to have regular production numbers so that stocking density remains close to optimal, mating and farrowing need to be managed to ensure an even placement of pigs.

Diseases influence individual pigs to different degrees and hence tend to magnify variance. Separating different ages in segregated production sections will limit disease transfer. Feeds and the feeding system have an equally strong influence. Inappropriate diets, abrupt changes in ingredients, poor grinding, inadequate mixing, deterioration in storage and feed separation during transport can all contribute to variation in pig performance and carcase quality.

Although both phase feeding and split-sex feeding have the potential to improve feed utilisation and lower the cost of production, they are difficult to apply in variable populations. Worse still, they can even extend the degree of variation by making inappropriate feed changes for those pigs furthermost removed from the mean of the population. Proper feeding by sex and careful rationing, especially the restriction of castrates at the end of the finishing phase, can lead to a more uniform slaughter pig.

All-in/all-out production systems have been shown to reduce the variation in growth rate relative to continuous-flow systems. However, where the slaughter pigs from a compartment or room are marketed as a single batch, their individual weights can be quite variable relative to situations where the group is sold over several off-takes. Sorting and weighing of pigs before slaughter is an effective way to improve the uniformity of slaughter pigs, but it is very labour-intensive.

At unit level, more variation between pigs will lead to more frequent deliveries to the slaughterhouse and therefore to a less efficient use of housing capacity.

There is the additional consideration that sorting and mixing are known to disrupt the pigs' social order. This in itself has the potential to increase variance, although its significance may relate to group size: it seems to be a factor of lesser concern in large groups. Small groups will be easier to manage and control, while big-pen systems will limit the mixing of pigs.

Influences from breeding

That then brings us back to the genetics of the animals. A known fact is that a wide range of growth characteristics in breeding stock will lead to a great spread of rates of weight gain in the progeny. Using one uniformly consistent type of parent-stock sow (an F1 cross) will make the final products more uniform, whereas resorting to the use of F2 crosses as parent stock tends to give more variation in the final product, because the sow side is more variable.

The message must be to rely on consistency in the female line and to restrict the boar side to one single terminal sire line of appropriate breeding value level (growth rate/backfat characterisation) in order to achieve more uniform progeny.

The choice of terminal sires needs to take account of various factors, of course, but one of the most important when pigs are being grown to heavier weights must be the point at which maturity occurs. A difference between individuals in terms of their maturation can strongly affect their relative daily weight gains in the latter phases of the finishing period. It is a major argument in favour of tailoring the boars used in slaughter pig production according to the target market served.

Our own genetic programme is based on one female product (an F1 cross between Large White and Landrace) and a differentiation of the terminal sire line. Traditional breeding enforced with modern technologies like BLUP and biotechnology has been used to develop a series of synthetic and purebred sire lines that are focused on uniform characteristics for growth, carcase and meat quality. Tailoring goes one step further, however. It divides a single terminal sire line into specialised sub-groups in which selection is focused on one or two traits of particular interest.

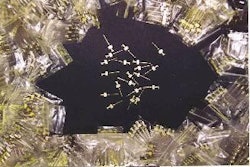

This practice of tailoring the boar has been demonstrated to give greater uniformity in the final product. Figure 1 shows an example of a Duroc population tailored for high backfat. The tailored group normally has a standard deviation that is reduced to 50% of its original value. This will in practice mean the difference between emptying a finishing room in 2 instead of 3 times. In so doing, finishing batches can much more easily be managed to hit the right place on the processor's carcase classification grid.

A certain boar population size is required, to be able to make tailoring feasible. Studs with 100 boars of a single line can do effective tailoring. For the producer it gives the advantage of working with a proven product and still directing some additional attention to the most important trait. It brings more of the slaughter progeny close to the target for carcase quality. In an example of backfat tailoring, around 15-20% in a "backfat-plus" segment creates a difference in estimated breeding value (EBV) of about plus 2mm. The phenotypic performance of tested pure-line animals will be around 4mm higher. Expected backfat differences in final products can vary between +1.6mm and +2.0mm.

In practice, tailoring has already proven to respond to specific customer needs and will push a top-performing system a couple of notches higher. For a genetic programme, the field results of various tailored boar groups give valuable evidence on how a certain selection performs in the market. It indicates the potential of a certain line, as well as warning if the product is starting to move out of balance at certain levels. In that way it provides information that can be used to fine-tune the breeding objectives of the overall programme and the tailoring of boars to suit the different markets for pigs around the world.