Last fall, the U.S. Department of Agriculture Food Safety and Inspection Service began a two-part study to set a baseline for a group of pathogenic and indicator organisms in unpasteurized liquid egg products prior to the addition of other ingredients. The first portion of the study is a three month shakedown period to be followed by a survey period lasting 12 to 15 months. Samples will be taken of liquid whole egg, liquid egg white and liquid egg yolk.

During the shakedown phase, each sample will be analyzed for Salmonella spp., Campylobacter spp., Listeria monocytogenes, Clostridium perfringens, Bacillus cereus, Enterobacteriaceae, generic E. coli, coliforms, and aerobic plate counts. According to the Food Safety and Inspection Service, the study “will provide the Food Safety and Inspection Service and the regulated industry with the data to understand the prevalence and quantitative levels of selected foodborne pathogens and indicator microorganisms. The data will enable the Agency and industry to work toward reducing the risk of foodborne pathogens in egg products by creating guidelines and potential standards for thermal processing.”

Current performance

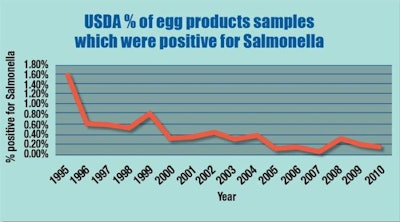

The Food Safety and Inspection Service has been testing samples of seven different kinds of pasteurized egg products for presence of Salmonella organisms for a number of years. Since 1996, 100 of the 25,072 samples of pasteurized egg products, 0.4 percent, tested by Food Safety and Inspection Service have been positive for Salmonella. The rate of positive samples has declined over time and was at 0.14 percent in 2010, the most current year for which data was published (see graph 1). The Food Safety and Inspection Service has also attempted to determine the serotype of Salmonellas found in the positive samples. Since 1996, Salmonella Heidelberg and Salmonella enteritidis were each found in 19 samples, and Salmonella typhimurium was found in eight samples, and all three of these serotypes are considered to be human pathogens.

Risk assessment

The U.S. Department of Agriculture Food Safety and Inspection Service conducted a quantitative microbial risk assessment for all Salmonella serotypes in pasteurized egg products. The assessment was designed to assist risk managers in evaluating egg handling and pasteurization performance standards for reducing the likelihood of Salmonella in pasteurized egg products and the subsequent risk to human health. Each of the seven major egg products categories was evaluated and an estimated annual number of human illnesses in the U.S. associated with consumption of these products were predicted (see Table 1). The risk assessment estimated that Salmonella in egg products is responsible for 5,525 human illnesses per year.

Pasteurized egg products are already relatively safe food products. Data from the current baseline study of egg products prior to pasteurization will be used by the Food Safety and Inspection Service to determine the number of logs of reduction that would be required to produce egg products that are even safer than they are now. The goal for the industry is to reduce the estimated number of human illnesses associated with pasteurized egg products to as close to zero as possible while still maintaining the quality and functionality of the egg products.

![Don Adams, vice president, sustainability, Keystone Foods, said “In the future, it may be necessary to have a good [corporate social responsibility] program to have a seat at the table.”](https://img.wattagnet.com/files/base/wattglobalmedia/all/image/2015/04/an.1204EIsustainAdams.jpg?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)