Each and every day, broiler meat further consolidates its position as the most nutritious and economical animal protein in the world. For this reason, those who work at the end of the poultry production chain have the responsibility to ensure the safety, quality and yield of processed birds.

Given the above, the objective of this article is to examine some ideas that are currently working successfully in many processing plants.

Individualized stunning

Stunning has always been a challenge for equipment manufacturers. This is because across the huge number of birds processed each day there is a great variety of individual weights, making it harder to adjust the variables that govern stunning. This becomes even more of a challenge when plants are processing birds that are unsexed.

Electric stunning systems have achieved high levels of success. However, day-to-day experience in the processing plant shows that more work is needed to improve this technology.

Recently, some suppliers of stunning equipment have started to offer systems that weigh every bird prior to stunning. This reduces hemorrhaging and broken bones, especially in the thoracic cavity, where fragile bones are located that easily conduct electricity. By reducing the amount of damaged carcasses, the profitability of the plant increases.

Washing

While birds are still in their cages immediately prior to processing, they continue to excrete waste from the digestive tract. Feces from those birds in the higher cages fall over those birds lower down the stack, soiling their feathers and skin.

When birds are hanging on the shackles of the overhead conveyor, some feces are dried and others are wet, especially around the vent, as a physiological response of chickens to this traumatic time.

Furthermore, during stunning some birds defecate when given an electric shock.

When passing through the bleeding tunnel, birds should be in a relaxed state. Yet, those that have not been properly stunned can be seen to be struggling. This movement compresses the intestinal tract, forcing feces out through the vent. Consequently, some chickens before entering the scalder can have a large organic load – feces – on their feathers and skin which, if not rectified increases levels of bacteria, raising the possibility of cross contamination during scalding.

In order to reduce the amount of fecal matter on birds once they leave the bleeding tunnel, many plants massage and wash the feathers and skin of birds using a special plucker that contains water containing 40 ppm of chlorine. This technology is recommended for speeds higher than 2,400 birds per hour.

Below this speed some plants have a double set of fixed washing brushes. The first set removes feces that are around the vent. Then, chickens pass through inclined brushes that open feathers as far as the skin and, with water under pressure, remove much of the feces on the body of the birds.

Scalding filtration systems

To complement the previous process, some equipment companies have developed a very effective technology that circulates the water in the scalder through a filter, similar to injection machines that recirculate brine. The purpose of this is to remove the organic load and discharge it into the waste water channel. As a result, water quality will be improved.

Water flow meter

In most poultry plants, sanitary authorities have determined that an additional 1 liter of water should be added to the scalder for each bird that enters it. Sixty percent of this water is to replace that lost on the feathers of the wet birds and 40 percent is added to keep the concentration of the organic load low.

Unfortunately, there are few plants that use water flow meters to achieve this parameter. Failure to do proper measure this flow can result in two worrying situations:

- If the water added is less than that required, the water level gradually decreases, resulting in birds not being fully immersed. This affects the quality of the scalding.

- If the water supplied is greater than a liter per chicken, total water consumption is greater than that really needed. This results in higher operating costs and consequently a higher cost per kilo or processed bird.

Addition of organic acids

Complementing the above techniques, some plants are using antimicrobials to maintain low levels of microorganisms in the scalder. One of the most used combinations of organic acids is sulfuric acid and ammonium sulfate.

It is important to remember that, at all times, the pH of the water in the scalder must be close to 2.0, in order to achieve maximum effectiveness of these strong acids.

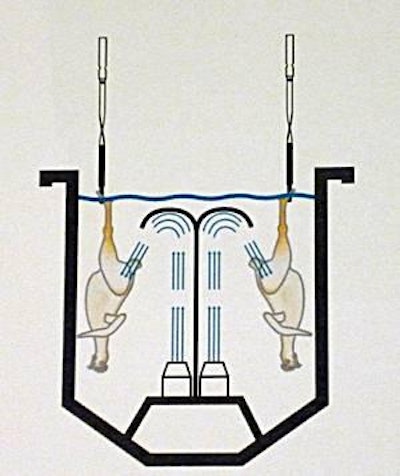

Water recirculation scalder

Water agitation is a sine qua non to achieve the proper raising of feathers down to the skin and the dilation of follicles releasing feathers, due protein denaturation process. Since the first online scalder came onto the market, various techniques have been used to agitate the water. Over time, the various technologies have improved:

- Mechanical agitation using propellers, similar to those on boats

- Agitation through pumping air into the bottom of the tank

- The recirculation of water through a waterfall system at the top of the scalder

When chickens are in the scalder, the position of the feathers is similar to that of an inverted umbrella.

The first two agitation techniques, open feathers from above to below and laterally, requiring more energy, because of the water resistance of feathers.

The latter technology, which agitates the water by falling from the top of the scalding operation, facilitates the opening of the feathers since the flow of the water is directed toward the bottom of the tank from whence a pump continuously recalculates it to the top. For this reason is greater efficiency. Additionally, efficiency is improved as, given that slightly lower temperatures can be employed, less fuel is needed to heat the water.

Brushing and washing eviscerated carcasses

To effectively remove all internal and external contamination, carcasses pass through a set of rotating brushes with water nozzles ejecting water with chlorine at 40 ppm. This combination of pressurized water and brushes ensures that the carcasses enter the prechiller totally clean. Any feces in the water prechiller will result in a high risk of cross contamination, affecting product shelf live. At this point it is imperative that all carcasses should be dry – with no water in the abdominal cavity.

In short, the techniques outlined above result in chicken that meets high quality and safety standards, reducing cost of operation.