explains how egg producers can develop their own HACCP programs.

Egg production is a seven-day-per-week business for all 52 weeks of the year; the hens never take a day off. Because of the nonstop year-round nature of the business and the relative isolation of many farm locations, it can be difficult for egg producers to get away from the farm for training.

With funding help from the American Egg Board, Auburn University personnel have created an online Hazard Analysis and Critical Control Points (HACCP) training program for egg producers that eliminates the hurdles of time and location and makes valuable certified training accessible to the entire industry.

Needed for HACCP certification

Many major food retailers and foodservice companies in the U.S. now require that their food suppliers operate under a Global Food Safety Initiative (GFSI)-approved scheme such as the scheme developed by the Safe Quality Food (SQF) Institute. One requirement of SQF certification is that the food processor must have a qualified HACCP program.

Laura J. Bauermeister, research associate, poultry science department, Auburn University, said the online egg HACCP training program is an introductory HACCP course which, upon successful completion, provides the student with a certificate from the International HACCP Alliance, which is required for SQF certification.

Bauermeister, who heads this training program, said: “The course is designed for students of all levels, whether they are going to be implementing a new HACCP program or working with an already established program. Again, we have tried to focus on convenience for the student so they don’t have days away from the plant and can finish the course on their time schedule and at their individual speed.”

“We have had a variety of people take the course; anyone who is on the HACCP team - including Quality Assurance and Quality Control personnel, maintenance employees, office managers, plant managers, and others - and anyone else in the company that needs a background knowledge of HACCP. We have even had a few students from some of the allied industries,” she said.

Develop a plan

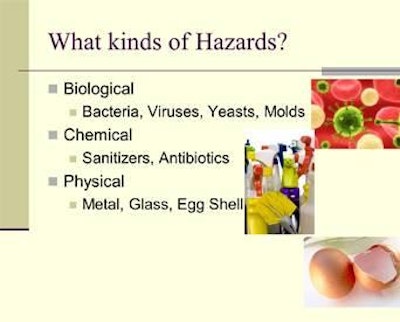

The core course materials are the seven training modules which are audio lectures with associated PowerPoint slides. Students also can view study materials for each lecture online or print them out for each lecture. The lectures can be stopped and started and replayed as many times as the student desires. Students must complete a quiz after each module with a score of at least 80 percent before they can advance to the next lecture. In addition to the quizzes, students also must score at least 80 percent on the final exam to receive their certificate.

As part of the course, students will begin preparation of a HACCP plan for their processing facility.

Additionally, they will have a HACCP plan partially developed during the course. Bauermeister said Auburn personnel will review these “partially developed” HACCP plans and will make suggestions for improvement.