The use of alternative raw materials, to reduce reliance on imported materials and improve sustainability, has been much discussed. Food security is high on the agenda for government and retailers, so research into homegrown crops and co-products is important. There are economic, logistical and agronomic reasons why these resources are not used to their full potential. However, this article will look at performance limitations and how various technologies can improve them.

Challenging materials

There are several challenges to formulating with alternative raw materials. They may be higher in fiber or include anti-nutritional factors (ANF). In particular, there are higher levels of insoluble fiber in crops like sunflower and oilseed rape (canola). Arabinoxylans form complexes with protein, reducing nutrient availability. Digestibility is therefore lower and results in more undigested material in the digestive tract. This in turn can encourage the proliferation of pathogens, which has a negative effect on poultry health and performance.

Consistency can be a particular issue when using co-products; nutrient profile and digestibility may vary between sources -- and even batches. In a recent experiment, four batches of Dried Distillers Grains with Solubles (DDGS) were each fed at two different levels to laying hens. There were significant differences in digestible energy and protein digestibility between the batches that were not correlated to differences in proximate nutrient composition. This unpredictability will have a corresponding effect on the productivity of the birds.

Processing for improvements

There are various options to process or treat raw materials prior to feeding in order to improve their nutritional value. Pulses may benefit from de-hulling to reduce both the fiber and ANF levels. Heat treatment has been used to improve digestibility of a variety of cereals and pulses. Micronization, in particular, has a positive effect on insoluble fiber meaning that nutrients have a longer time to be digested and absorbed.

The use of enzyme pre-treatment for co-products like DDGS and rapeseed meal has been investigated. The use of proteases is particularly interesting to make protein more digestible before it is fed. Phytases are already used in ethanol plants, resulting in lower levels of phytate in DDGS. However, cost and logistics currently preclude these kinds of processing despite the significant opportunities.

Enzyme technology

Enzyme technologies can help to improve feed formulation precision, diet efficiency and ultimately performance by reducing raw material variability. They also have the potential to complement endogenous enzyme production, sparing energy. When formulating with alternative raw materials there is more potential for enzymes to have a positive effect than with standard diets.

Luis Romero, Danisco Animal Nutrition stated, “In general, you see bigger energy and protein digestibility improvements with alternatives.”

This is particularly true for the disruption of protein-fiber interactions, which are important in DDGS, rapeseed and sunflower.

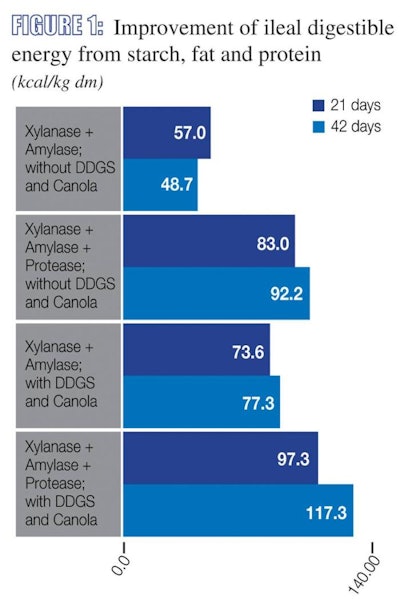

A recent broiler digestibility study looked at the effects of adding high-fiber ingredients to both corn and wheat based diets. Corn DDGS and rapeseed meal had the effect of reducing the availability of protein in particular. Greater effects of enzymes were found in the higher fiber diets, increasing the combined energy contribution of protein, starch and fat (see Figure 1).

“The additive protein digestibility effect of protease on top of xylanase and amylase was also demonstrated,” Luis reiterated.

The lower digestibility of alternatives means there is the potential for more undigested material in the poultry digestive tract. This creates an environment that is favorable for pathogen growth, making birds more susceptible to enteric disease. Xylanase is able to create the prebiotic compounds arabino-xylo-oligosaccharides from cereals. They encourage the growth of beneficial bacteria and the production of short-chain fatty acids.

Performance benefits

A number of investigations have been carried out to demonstrate the efficacy of enzymes in diets containing alternative raw materials. These recent examples were presented at the XIVth European Poultry Conference 2014 and are summarized below.

In two trials, broilers were fed diets made up of corn, corn DDGS, soybean and rapeseed meal – supplemented with either xylanase or xylanse and beta-gluconase. The enzyme combination significantly improved FCR and ileal digestibility energy, compared to the control. Both treatments significantly improved starch digestibility and tended to improve ileal fat digestibility (see Figure 2).

Another study fed broilers diets containing three different levels of rapeseed and sunflower meal; with or without an enzyme combination, i.e. xylanse and beta-gluconase. Birds fed diets with high (H) levels had lower weight gain and poorer FCR, compared to those fed the medium (M) or low (L) treatments. Enzyme supplementation was shown to significantly improve FCR for the three diet types, with the highest response being seen in the H treatment (see Table 1).

Novel strategies

The combination of different groups of feed additives with potentially complementary modes of action, e.g. probiotics and enzymes, has also been investigated. These can help improve digestibility, support a healthy gut microbiota and improve bird liveability. In trials with non-challenged broilers fed a corn-soy diet containing some fibrous cereal byproducts, significant incremental increases in nitrogen corrected apparent metabolizable energy (AMEn) with additions of a three-strain Bacillus probiotic and xylanase, amylase and protease enzymes. Luis commented, “This combined mode of action further improves the digestibility of alternative raw materials.”

Older birds deal better with solubilized fiber due to gut maturity. This is why the use of some alternatives is limited or precluded in younger poultry. By having a maturation effect on the intestine, the combination of enzymes and DFMs could allow some increase in levels. Laying hens, breeders and turkeys have longer lifecycles, and so have a larger fermentative capacity and are able to better digest fiber. Therefore, there is even greater potential for enzymes to improve performance in diets containing alternative raw materials.

Future possibilities

With advancements in enzyme technology it is possible to significantly improve poultry performance when fed rations containing alternatives. By improving the digestion and absorption of nutrients, nutritionists are able to make greater use of ingredients like DDGS, rapeseed and sunflower. This offers flexibility when formulating different types of diet, dependent on both the cost and sustainability of the raw materials.

Research has shown that enzyme combinations are particularly effective, when feeding alternatives. Whilst carbohydrases help to improve fiber digestion, proteases are interesting to get more value from lower quality protein sources. Enzyme producers are looking at the possibility of creating raw material specific matrixes for their products. This would enable formulators to better predict the nutrient value of alternative raw materials, particularly when there is variability. Creating confidence in consistent poultry performance when fed rations containing these products. Then potentially alternative feed ingredients can be included at higher levels, benefiting both efficiency and environmental impact.