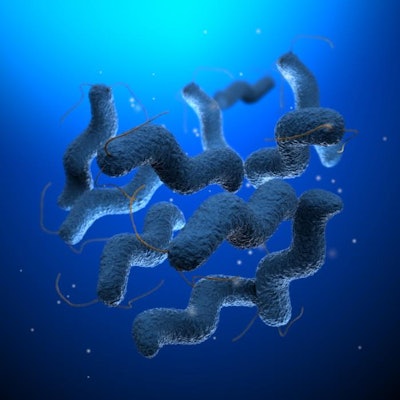

Campylobacter is the most frequently reported foodborne cause of illness in Europe, affecting an estimated 9 million people each year, according to the European Food Safety Authority (EFSA).

Contaminated poultry remains the most significant source of human infection, and the European poultry industry is implementing various strategies to reduce contamination levels.

Poultry International spoke with representatives from two of the U.K.’s largest poultry companies – Ursula Lavery, technical and R&D director Europe at Moy Park, and David Keeble, technical director at Faccenda – about the steps their companies are taking to reduce contamination.

POULTRY INTERNATIONAL: How much poultry meat do you produce annually, and what Campylobacter reduction measures are you taking?

Ursula Lavery, of Moy Park, argues that all steps for controlling Campylobacter from farm to finished product are equally important. | Courtesy Moy Park

LAVERY: We process more than 5.5 million fresh chickens per week; 1.3 million turkeys per year; and 200,000 tons of added-value products annually, and are the largest producers of organic, free-range, and higher-welfare chicken and turkey in the U.K. and Ireland. Our Moy Park-branded products are supplied to leading retailers, including Waitrose, and foodservice providers throughout the U.K., Ireland and Europe.

We take a holistic approach to reducing Campylobacter levels throughout the supply chain – from farm to factory to finished product – but all steps are equally important to deliver a cumulative reduction. Our action plan centers on seven principle pillars:

- Research and analysis by a dedicated Campylobacter team in collaboration with leading scientists and academics in the U.K. and Ireland giving a picture of seasonal Campylobacter trends that we benchmark with producers globally.

- All new farms are built with specific Campylobacter control systems.

- Enhanced biosecurity systems, including double barrier access to the sheds and hygiene controls, and hot water heating in more than 85 percent of our farms to provide a drier environment for the birds.

- Good farming practices are incentivized around animal welfare, biosecurity and agricultural compliance.

- An optimized thin and clear management protocol.

- Use of state-of-the-art processing facilities, optimized factory procedures and segregated packing lines.

- Moy Park was first to market with “no need to wash” labeling on its whole birds, and we include consumer information on safe handling and cooking of poultry on all products. We also use hermetically sealed and leak-proof packaging, and have developed award-winning cook-in-the-bag products.

KEEBLE: Faccenda is the U.K.’s second largest chicken processing company, processing around 2 million chickens and 70,000 turkeys each week, with turkey production more than tripling during the Christmas period. Our poultry customers include the majority of the U.K.’s major supermarkets, as well as well-known foodservice chains.

At the heart of our Campylobacter reduction program – which covers the supply chain from farm to product packaging – is SonoSteam, which reduces Campylobacter levels by applying steam and ultrasound to the neck and skin of each chicken as it passes through the machine.

We have implemented new biosecurity procedures on our farms in personal protective equipment, cleaning and hygiene, and use barrier, and double barrier, systems. We’re also looking at how the gut health of our chickens, especially when very young, has an impact on Campylobacter levels.

Zones within our packaging lines separate team members who work with raw, packaged, and chicken products. Packaging plays a huge role in food safety, so we use a thick “no-leak” barrier film and modified atmosphere packaging to help keep the product fresh. We were the first producer to introduce roast-in-the-bag packaging in 2013, which eliminates the need for consumers to handle raw chicken.

Providing our people with the right level of training and support has been critical.

POULTRY INTERNATIONAL: How effective are these approaches?

LAVERY: Our initial research in 2009 allowed us to establish a baseline to better understand this complex bacterium. Our published findings in 2015 showed that, as a result of our supply chain intervention trials under the Moy Park/Waitrose joint “Farm to Fork” Campylobacter Action Plan, the proportion of fresh whole chickens with Campylobacter present at the highest level (>1,000 cfu/g) at the end of March 2015 had fallen by two-thirds.

Providing people with the right level of training and support to control Campylobacter is critical, said Faccenda’s David Keeble. | Courtesy Faccenda

KEEBLE: Factory trials of SonoSteam in 2014 saw an 80 percent reduction in Campylobacter on neck and breast skin. Full implementation was initiated in 2015, and it’s now running on both our primary processing lines.

Throughout the testing period of the U.K. Food Standards Agency (FSA)’s retail survey, we saw consistent reductions in Campylobacter levels. Based on our own independent testing, Campylobacter levels on our products have been consistently below the FSA’s retail target of less than 10 percent for highly contaminated chickens.

POULTRY INTERNATIONAL: How do these measures differ from those of competitors?

LAVERY: The industry has worked collaboratively to share best practices through the FSA Acting on Campylobacter Together (ACT) working group. However, one of the cornerstones of our success is a holistic approach and a patented technology we developed using a thermal process integrated into our production lines.

KEEBLE: A number of other approaches are being used within the industry, from focusing primarily on agricultural changes to rapid chilling and secondary scalding in the factory, but our experience suggests the most effective approaches include action throughout the supply chain.

POULTRY INTERNATIONAL: How do initiatives to reduce Campylobacter contamination levels in poultry in the U.K. stack up against measures in other countries/regions?

LAVERY: Although Europe is carrying out some progressive work, the U.K. is leading the way in terms of reduction strategies. Countries outside the EU operate in different regulatory environments where their approach permits antimicrobials, so they have additional tools they can use.

KEEBLE: We have worked with our own supply chain partners on the continent to help understand what interventions are used and what best practice looks like elsewhere, and we’re open to testing or trying new interventions.

POULTRY INTERNATIONAL: What more can be done to reduce the problem?

LAVERY: Our next strategy will be to analyze the organism and how it interacts with the bird and the abiotic environment. We will continue our focus on R&D in key project areas, and are investing in PhD research programs for two members of our expert team, which will look at biosecurity, on-farm management practices and genome sequencing.

We are extremely proud of our progress to date, and proud to receive the Safefood Best Innovation to Enhance Food Safety Award at the recent Northern Ireland Food and Drink Awards.

KEEBLE: The industry has responded well to the challenge laid out by the FSA. We are trying some new interventions that look promising and, if effective, we’ll share what we’ve learned.

Tackling Campylobacter and its effects on consumers is a partnership between producers, retailers and consumers. Continuing to educate consumers, particularly on kitchen hygiene and the importance of not washing raw chicken, is essential.

How to control Campylobacter in broiler production

www.WATTAgNet.com/articles/26847