There is a global trend in the poultrymeat industry worldwide towards further processing to meet the growing demands of an increasingly cash-rich, time-poor and sophisticated population. The rate of development of the further processed market varies widely between countries but perhaps nowhere is the trend more advanced than in the USA.

Estimates of the proportion of poultrymeat sold in further processed form are hard to come by and surveys can be difficult to interpret. However, it is clear that cooked further processed sales by turkey companies participating in the Agristats/National Turkey Federation marketplace surveys have increased significantly. Sales of cooked items have increased from just over 13% of total turkey tonnage sold in 1994 to almost 23% in 2005, the year of the most recent survey. There are no signs of a slow-down: US turkey companies have opened three new cooking facilities in the last two years and four new slicing plants in the last five years, and some existing plants have added slicing capability. Chickenmeat processing is following the same trends.

Today's US poultry products meet the strong demands in the ready-to-eat and ready-to-cook sectors. A tour of the recent International Poultry Exposition in Atlanta and discussions with exhibitors highlighted ways in which equipment manufacturers are helping the industry there to meet the growing demands for these further processed products.

Increased efficiency

This was the most noticeable trend in further processing equipment, with new models that have a higher capacity, are more efficient and waste less than previous designs.

Waste reduction was one of the guiding principles behind the design of the FXplus Slicer from Formax. This is achieved through two independent feeder drives, which allow logs of cooked meats to be sliced right to the very end. With back-clamp and continuous feed options, waste is significantly reduced, an important feature for high-value products. Just coming onto the market is the company's PowerMax4000 with an even larger capacity, thanks to its four independent drives.

Labour saving

Another consistent trend was the goal of labour saving. Labour has always been a costly part of further processing, especially in developed countries like the USA, and this aspect has been brought into even sharper focus with the coming of greater controls on the employment of cheaper immigrant labour.

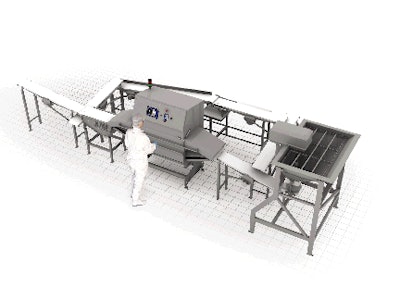

It makes sound economic sense to automate processes in order to minimise labour costs. For example, AEW Delford and Scanvaegt members of the Marel group are active in loading and batching technology with their respective IPL Batcher and Robobatcher. These intelligent batching systems offer processors the ability to load pre-formed trays with product to produce fixed-weight packs. The equipment eliminates a great deal of costly labour, whilst delivering attractive packs with a minimum of give-away.

More flexibility

Maxum 700 forming machine from Formax offers increased throughput with flexibility. Product mix can vary significant between customers so quick and easy changes are important features. The company offers a wide range of templates to form different shapes and sizes of product. Changes can be made easily and quickly, giving maximum flexibility and minimum downtime between batches.

Another example of meeting the driver of greater flexibility was the CFS MultiFormer 600. As well as increased production variety, it also offers shorter tooling changes, reduced maintenance cost and time, reduced waste and maximum hygiene.

Healthier products

With rising obesity and chronic diseases in developed nations, there is a growing demand for healthier products. As it is low in fat, poultrymeat can help to meet this demand.

Even popular fried products can be marketed as that little bit healthier if the fats or oils used are less saturated. The disadvantage for the processor is that such oils are more prone to oxidation and require gentler handling. At IPE, MP Equipment Company introduced a new frying system using an efficient heat exchanger to raise the temperature of the oil for cooking. This indirect form of heat causes less damage to the oil than a direct heat source or flame.

On the FMC stand was the Stein TFF-II ThermoFin fryer. It incorporates a new centrifugal filter for the hot oil, removing particles that can break down the less saturated, healthier oils.

Addressing food safety concerns

One recent and very extensive food recall involving beefburgers in the USA highlighted the vital importance of food safety issues and the potential for catastrophic financial impacts on a business when things go wrong.

Two aspects of food safety were in evidence at the show. Firstly, ease and efficiency of cleaning and sanitation were mentioned by all equipment manufacturers interviewed. They emphasised how design and materials have been refined for easy cleaning and sanitation. For example, hollow tubing and awkward joints where debris can accumulate have been eliminated from modern designs, and equipment can be cleaned and sanitised effectively without damage.

Another aspect of food safety is the elimination of foreign bodies and bones from poultrymeat products. These can present a hazard of choking or injury to the consumer. Marel featured its SensorX automatic bone detection system, which detects bones and other foreign bodies in real time and displays on a high-resolution screen for easy product removal from the line.

Other trends

Consumers can be hard to please. They demand further processed products to make their busy lives easier. On the other hand, they do not want the products to look processed: their families and guests should believe that the meal has been cooked from scratch at home. FMC is helping to meet this demand with Stein's new 5-Star Homestyle Breader. This delivers a slightly inconsistent and less-than-perfect look to products such as popcorn chicken.

.jpg?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)