Aviary housing systems offer layers access to litter to express natural behaviors, such as scratching, foraging and dust bathing. However, air quality in cage-free systems may be compromised as dust (particulate matter) and ammonia increase as manure and litter accumulates on the floor.

Dust, which can serve as a carrier of microorganisms and endotoxins, is a significant health risk for both farm workers and the birds as fine particulate matter can enter into the respiratory system. Ammonia, likewise, can cause respiratory tract irritation or damage.

Dust control in cage-free houses

Recent studies have shown that cage-free housing results in six to nine times higher dust in the house environment than cage systems with manure belts. Researchers in Europe and the U.S. have explored many potential approaches to controlling dust including ionization with electrical charges using metal wires on the ceiling. Other studies have focused on spraying litter with treatments including tap water, acidic water, soybean, canola or rapeseed oil and combinations of water and oil.

Research at Iowa State University led by Drs. Hongwei Xin (project principal investigator, distinguished professor and director of the Egg Industry Center) and Lilong Chai (co-principal investigator and post-doctoral research associate) is now focusing on a control measure utilizing electrolyzed water supplemented with litter additives as needed.

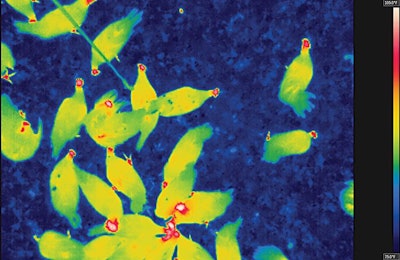

Supported by promising results from laboratory trials, the research has now moved to a commercial layer farm using an aviary production system in Iowa. Electrolyzed water has been used in the food processing industry for many years. Sodium chloride is dissolved in tap water and subjected to an electrical charge. The dose of sodium chloride and duration of electrolysis in the reactor can be controlled to produce slightly acidic water with different concentrations of free chlorine. In the laboratory trials, Dr. Chai reports that “we have seen significant reduction in particulate matter and bacteria in the air and litter without causing increased ammonia levels.”

Helping control airborne bacteria is an especially important benefit that is not offered by some other control methods. The free chlorine is responsible for that anti-bacterial effect. Impact of the free chlorine is determined by the length of time the water is aerosolized.

Electrolyzed water is applied via a spray nozzle system that is suspended above litter aisles of the house and reaches most of the open litter area in the field trial house design. Based on the laboratory experiment results, the field trial is being conducted with a spray volume of 125 milliliters per square meter (approximately 4 fluid ounces per 10 square feet) corresponding to 1 centimeter (0.4 inch) litter depth. The application amount may be adjusted as litter accumulation on the floor changes. It is estimated that combined initial investment and operating costs are from $.04 to $.05 per bird per year.

The spray system is also able to be used as a tool to cool birds during hot weather. As water evaporates from the wetted birds, it removes body heat and hence, lowers body temperatures. This also means that in cold weather birds will experience a similar short-term cooling affect when the spray is used to control dust.

Balance between dust and ammonia

The trick in managing litter is to keep it dry enough to prevent bacteria from breaking down the uric acid in the manure into ammonia, without the litter being so dry that bird activity in the litter creates airborne dust.

Litter amendments have also been used in combination with the electrolyzed water project or independently to reduce litter pH. The gaseous release of ammonia can be reduced as a lower litter pH (below 7) converts ammonia into ammonium.

There are many types of litter amendments available in the market. Some chemical examples include sodium bisulfate, aluminum sulfate and ferric sulfate. Naturally occurring products include zeolite, gypsum, and a combination product of diatomaceous earth and calcium bentonite which is approved for organic production (also available with citric acid). Another category is that of microbial additives.

The commercial house field trial will be completed in the summer of 2018 and final results and recommendations will be available for consideration by producers. When his work on this project has completed, Dr. Chai will assume a faculty position at the University of Georgia working in poultry research and extension.

Layer house emissions under close scrutiny in europe

Dr. Albert Winkel, livestock and environment researcher, Wageningen University, the Netherlands, offers a warning to the U.S. egg industry. “We have learned that moving to cage-free production has solved an animal welfare problem, but has created another serious issue – environmental contamination.” In fact, since European Union Directive 2008/50/EC was established agriculture has received much attention as a source and a solution to the problem.

In the Netherlands, agriculture ranks #3 behind automobiles and factories as a source of particulate matter in the environment. Other parts of Europe with a high agriculture and human population concentration such as Germany, Belgium and northern Italy are also focused on the issue. In an attempt to meet the standards of the directive, the Netherlands has implemented a permitting system to regulate new construction and remodeling of current animal housing. Dust, odor and ammonia emission projections are individually calculated based on emission factors for each species, housing system, type of animal (layers, broilers, etc.) and number of animals. A dispersion model calculates emissions in the vicinity of a site for 10 years based on meteorological data for the specific farm. These calculated emission projections are then compared to the dust limit values of the directive before approvals are granted.

Layer producers in Europe using aviary systems have used several methods to manage dust, ammonia and odor, both in and outside the layer house. Heat exchangers by design are quite effective in reducing particulate matter emissions with filtration before exhausting house air. Taller exhaust chimneys are used which dilute dust concentration. An important tool inside the house is use of automated litter scrapers for the floor level. Dr. Winkel's soon-to-be published research has shown that litter depths kept to about 1 inch reduces particulate matter and ammonia by 25 percent. And a final important environmental control method is the use of manure drying tunnels located next to the layer barn. This equipment uses warm exhaust air from the barn to dry manure on perforated belts. Upon forcing air through the manure layer, particles are filtered out. Dry matter content increases from 30 percent coming from the barn to 80 percent or more after processing which considerably reduces manure disposal fees for farmers.

Researchers at Wageningen University are now working on new aviary design concepts that will reduce environmental contaminants. One promising concept being studied is to separate the birds’ clean and dirty activities into separate rooms. In the clean room birds will eat, drink, perch and lay eggs and have free access to the other room where dust

bathing and scratching in litter will be available. The results are still two years away, but offer new approaches to solving some of the environmental issues with cage-free egg production.