Growing edible meat products without an animal: It sounds like something out of science fiction. But, it’s becoming reality as scientists, startups and venture capitalists pour resources into the emerging technology.

While even the most optimistic assessment places the product years away from the grocery store, the novelty of the technology is attracting press around the world as well as the attention of the animal agriculture business. Already beset by a changing market for their products and the transition to new animal husbandry methods, this technology seems like another challenge for the poultry industry. But, is it?

The state of the art

Right now, the technology exists to yield an edible meat product – called lab-grown meat, in vitro meat, cultured meat or clean meat. However, the process is still far from creating a competitive product.

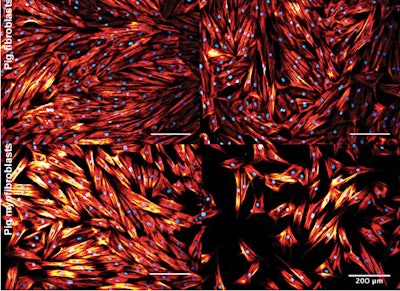

Dr. Paul Mozdziak, a leading mind in the field of cell culturing, who’s focused on poultry application of the technology, explained the process. A sample of muscle tissue is collected from an animal, either dead or alive, and is ground up. The tissue is then treated with enzymes that digest away myofibril and contractile proteins and release muscle derived cells. Those cells are placed in a cell culture dish with a defined cell media or undefined cell media, which has an animal serum component, so they reconstitute as muscle tissue, or what’s being called cultured meat.

Mozdziak, a professor in the Prestage Department of Poultry Science at North Carolina State University, said this is not a novel process. What is new is the level of excitement surrounding the process.

“There’s a lot of people out there with ideas and getting money, and there’s not been a lot produced to practice right now,” Mozdziak said. “The question is, ‘What’s the first product going to be? What’s the first product going to look like? Where is the space going to be in the next two to three years?’ and it could be a very exciting time.”

Dr. Paul Mozdziak (left) is a leading researcher in the field of culturing poultry tissue. | Courtesy New Harvest

Hurdles to market

The largest technical hurdle may be that the current process can’t yield a product exactly like what’s in the meat case. Meat is made up of more than just muscle cells. They include connective tissues, blood and fat, too.

An on-going challenge in growing tissue is developing thickness. The tissues are not vascularized Mozdziak said, so the serum used to grow the cells cannot get to the center of a dense chunk of tissue. Without vascularization, growing large pieces of meat is exceedingly difficult. Making a more complicated cut of meat requires vascularization as well as the ability to synthesize the other elements of what makes meat.

The second major hurdle is the cost of the process. In March 2017, an article in The Wall Street Journal on startup Memphis Meats said its current technology creates a pound of chicken meat for “less than $9,000.” Mozdziak said key contributors to the high price tag are the necessary infrastructure: cellular serum and media, laboratory facilities, and a bioreactor where tissue can be grown.

If someone develops a process and is able to scale it, this will help with costs. Even then, the price of cellular media will still contribute to a higher cost than conventional meat products.

“It’s going to be a long time, in my humble opinion with my 25 years of cell culture experience, before its anywhere near what the cost of classically raised meat is,” Mozdziak said.

Cultured meat technology uses cell culturing to grow new muscle tissue from a sample of animal tissue. | Johanna Poetsch, iStockPhoto.com

How far away is a competitive product?

Opinions differ on how soon a product may debut, but there is agreement that the product won’t be publicly available for a number of years.

Mozdziak said a demonstration product could be available in three to five years. But, something that will be price competitive and widely available could be as far as 20 to 30 years away. An important factor worth considering is whether the product will be a mix of muscle tissue and plant-based proteins that’s sold as cultured meat, or something more complex.

Citing others in the sector, Dr. David Welch, director of science and technology for the Good Food Institute (GFI), said a product may be available in a high-end restaurant within three to five years, could be commercially available in five years and price competitive within the next 10 to 15 years. Welch said the GFI is an accelerator for, and promoter of, plant-based foods and the cultured meat sector.

Welch’s confidence stems from the proof offered by startup companies, like Memphis Meats, that it is already possible to create the product on a small scale. There’s no “huge red flag” showing the technology does not exist, he said, and the science community, with expertise in stem cell work and culturing human tissue, is moving into the meat sector, too. The other key ingredient, Welch said, is more money lining up behind the product.

Erin Kim, communications director for cellular agriculture research group New Harvest, was more skeptical and – citing organizational policy – declined to make predictions. However, she said the research surrounding the product is limited, as is the funding to support it, and that shows in the current lack of any kind of product. New Harvest, a non-profit group involved in advancing cellular agriculture research, is providing funding for Mozdziak’s research.

“We’ve seen a lot of talk, a lot of predictions about the market availability,” Kim said. “But it’s 2018 now and there still is no cultured product whether it is chicken, or beef or something else. I think that says a lot.”