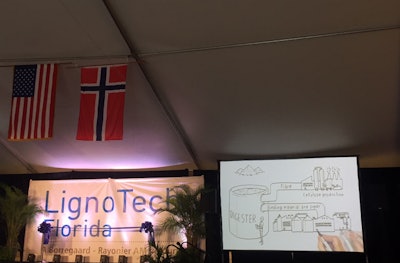

As sustainability becomes increasingly important to both agribusiness companies and consumers alike, a new lignin plant on Amelia Island, Florida, is making a positive impact on not just the environment, but also the local community. LignoTech Borregaard, in partnership with Rayonier Advanced Materials (RYAM), recently hosted a grand opening for its new $110-million LignoTech Florida plant on June 26, including a tour of the state-of-the-art plant.

From left: Len Kreger, Jan Anders Oksum, Per Arthur Sørlie, Paul Boynton, Jimmy Petronis, David Brown | Alyssa Conway

Lignin’s environmental impact

Lignin is a natural chemical produced by growing plants. It is the sustainable byproduct of trees, which binds the cells of trees to make them rigid. It often serves as a natural, renewable alternative to petroleum-based products, according to LignoTech Florida, and is also used as an effective, sustainable binder in animal feed and in crop protection. As a byproduct of pulp processing, converting lignin into a usable product means fewer carbon emissions are released into the air.

“When have you ever heard of a new plant opening that will be good for the environment? Well, that is the story of LignoTech,” said Florida Sen. Aaron Bean who served as the master of ceremonies for the grand opening event.

Building the state-of-the-art plant

The new LignoTech Florida plant brings together LignoTech’s conversion technology, sales and marketing, and operational responsibilities, with the raw materials from RYAM’s sulfite pulping process and other utilities and services – a long journey that started in 2014, according to Peter Morris, managing director. In 2015, after final agreements were signed, product testing began to see if it would work. In 2017, construction of the LignoTech Florida facility and recruitment of the first round of employees began. And, finally, in 2018, the project was completed safely, on time and on budget after nearly 400,000 hours of work. In early May 2018, the company began liquid lignin production and began powder production in early June 2018. The plant is operating at a 100,000-metric-ton capacity but at full capacity is expected to produce 150,000 metric tons per year of product, according to LignoTech.

“Really this is a win-win situation for both parties and the environment,” Morris said.

The new LignoTech-RYAM plant has been designed with employee and customer needs in mind.

The plant produces lignin in powder and liquid forms to serve clients in a variety of different applications beyond animal feed, such as concrete admixtures, pesticide dispersants, battery expanders, oil well drilling chemicals and emulsions. The plant is designed in a way that enables it to shift staff from one area or another – focusing on liquid or dry product – depending on its diverse range of client needs at the time. According to the plant’s supervisors, cross-training is the key.

Keeping safety at the forefront, the LignoTech Florida plant was designed with many features to keep employees safe and operations running smoothly. A few of these include fail-safes that prevent machines in the plant to operate unless a worker is on duty or automatically shut down operations when a problem is detected, a control room that allows employees to monitor the entire plant and production levels from various computer monitors, tools to monitor Florida’s changing weather, and forklifts on the floor that have a capped speed for the safety of the operator and other employees on the floor.

Plant creates jobs on Amelia Island

“It wasn’t that long ago that I was very concerned the … mill would close down. And I started thinking what happens when I see a mill shut down in a community and the devastation that happens to the jobs that take place there,” said Jimmy Patronis, chief financial officer of the state of Florida, praising the leadership that helped keep the project on track.

The new LignoTech Florida plant is dedicated to providing jobs for the local economy, recruiting largely from Fernandina Beach and the broader Nassau county. In fact, 58 percent of the plant’s employees reside in Nassau county, with 26 percent living on Amelia island.

The new plant also creates opportunity for young people to begin building their careers in their hometown, Morris said.

Other grand opening highlights

The new plant’s grand opening ceremony provided the opportunity for all parties involved in the new plant coming to fruition to network and celebrate the LignoTech-RYAM partnership. A “blending of cultures” to celebrate the American-Norwegian partnership was hosted, featuring two traditional musical selections from Norway and two from the U.S.

Fernandina beach vice mayor, Len Kreger, also presented Morris with a key to the city.

From left: Sen. Aaron Bean, Vice Mayor Len Kreger, LignoTech General Manager Peter Morris | Alyssa Conway