Nanotechnology acts as a filter to trap avian influenza viruses for quick identification without dependence on antibodies. Dr. Mauricio Terrones, distinguished professor of physics, chemistry, materials science and engineering at Penn State University, will present this nanotechnology at the Poultry Tech Summit in Atlanta, November 5-7, 2018.

Now moving toward commercialization, the nanotechnology is for the detection of avian influenza but later could be applied to other poultry viruses of commercial importance.

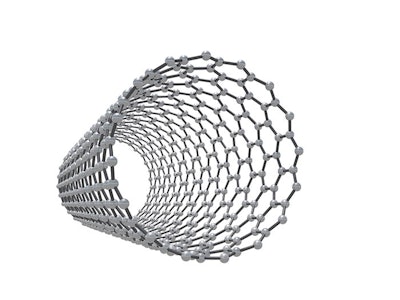

The nanotech device, which measures 1 square centimeter, uses aligned nanotubes grown and constructed from carbon to trap the avian flu virus, which is about 100 nanometers in diameter.

This nanotechnology offers a number of benefits for poultry production:

- It works at very low concentrations of viruses, and unlike polymerase chain reaction (PCR) technology, produces no false positives.

- Detection is improved by a hundred times or more.

- There is no requirement for development of antibodies.

The developers foresee the technology also leading to the replication of viruses for the manufacture of vaccines.

Controlling structure with atomic precision

Terrones and his team have spent four years of research to control the spacing between the nanotubes.

“If you can control the growth of nanotubes, you can catch certain things; it works like a filter. That's when we started thinking about viruses," he said.

This technology is an early diagnostic tool to find viruses when you have no idea what they might be, Terrones said. In an avian flu outbreak, this technology allows for isolating the virus and determining how it mutated. It can then be replicated, and vaccines can be developed.

When viruses mutate, surface and also genetic material change by 1 or 2 percent. Mutations are very fast and, as we all know, can happen from chicken to chicken. However, with mutations, the size of the virus does not change, and to catch them, there is no need to develop a new antibody. With aligned nanotubes, "the interesting thing is that we can catch them, even if it's a new virus, and then do the sequencing to determine what kind of virus it is," he said.

The sample is placed in a 1 sq. centimeter microfluidic device containing iron particles. Through the inlet, the material is injected to catch the viruses.

“What’s interesting here is that you have a three-dimensional filter in which you control the spacing for the different types of viruses," Terrones said.

Most viruses are in a size range of 25 to 500 nanometers. Once the device is opened, the nanotubes are removed and placed in the electron microscope to see what has been obtained. Then, the collected virus is injected — along with the nanotubes — into a specific-pathogen-free (SPF) egg to replicate them.

For more information about the Poultry Tech Summit and to register, visit: www.wattglobalmedia.com/poultrytechsummit