Cultured meat production promises to improve sustainability and animal welfare, however the new technology still needs to overcome several challenges before it can come to market.

“Is cultured meat going to deliver on its promise? Absolutely,” Benjamina Bollag, CEO and founder of cultured meat company HigherSteaks said on September 18 during the 2020 Future Food-Tech Summit.

“The variety of cultured meat products in progress is astonishing. However, there are still some challenges that we need to overcome before everyone can have cultured meat on their plate.”

Stem cell choices

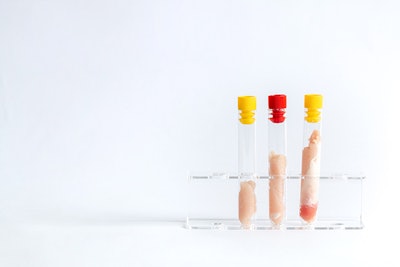

Cultured meat is made from the cells of real animals, so the resulting product could taste like chicken, steak, pork or more. The process begins by isolating relevant stem cells that are found in muscle tissue.

“There are many different types of stem cells that people can work with. Each of them has their own challenges. Some, for example, are more applicable, while others are harder to differentiate,” Bollag explained.

Growth medium costs

Stem cells require something called a medium to grow and reproduce. Growth medium can cost up to $400 a liter. One kilogram of cultured meat can require up to 600 liters of growth medium, so costs can add up quickly.

Bioreactor design

The stem cells and growth medium ferment in large tanks called bioreactors. The equipment used is like the equipment used in microbreweries, although more specialized.

“Bioreactors are another major challenge. We urgently need to create closed automated bioreactor systems. By doing this, we would create a system that is completely closed to the outside environment and drastically limit human interaction so that the cultivated meat can remain completely sterile without the need for antibiotics,” Bollag said.

Scaffolding decisions

Stem cells need structure to form shapes and cultured meat start-ups are still investigating to find the right biomaterial for the job.

Regulatory pathway

The regulatory pathway to approve cultured meat products and other meat alternatives is still in development. This process will be less stringent than the pathway to approve new therapeutics, but as of yet, no cultured meat start-up has obtained regulatory approval.

More capital is needed

Investment in meat alternatives reached a record high of $930 million during the first quarter of 2020. A majority of the funding went towards the development of plant-based meat and egg alternatives, but interest in cultured meat is also growing.

“Cultured meat is a capital-intensive business. The manufacturing world requires significant investment that a company will have to raise quickly in order to scale at the rate they need,” said Bollag.

Consumer acceptance

Ultimately, consumer acceptance is needed before cultured meat can be considered successful. A recent study revealed that nearly three-quarters of Generation Z is still unsure about this meat alternative.

“To reach the mass market, we still need to educate the consumer further,” Bollag said.

Like what you just read? Sign up now for free to receive the Poultry Future Newsletter.