Mississippi State University has opened a new biosecurity level 2 (BSL2) research laboratory to help researchers investigate possible treatments for pathogenic bacteria that affect the poultry industry.

“The lab itself is a facility which will allow the industry to have a place where research can be conducted that will help them fight disease issues that they may be experiencing in the actual commercial setting. That’s really what this facility is all about,” Aaron Kiess, Associate Professor in the Department of Poultry Science at Mississippi State University.

“We have traditional facilities where we run a multitude of different research trials, whether that be physiological, nutritional or production. But the new facility allows us to actually mimic a disease challenge. For instance, in the BSL2, we’re looking at pathogens and bacteria like Salmonella, Escherichia coli, Campylobacter and Clostridium, things that are associated with disease in the poultry industry.”

A place to safely investigate pathogens

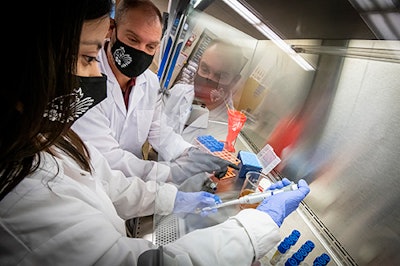

In biosecurity level 2 laboratories, researchers can safely work with moderate-risk agents. In this case, to test the effectiveness of possible antibiotic alternatives against common pathogens that can infect poultry.

“It’s been a few years now that research has found that the use of antibiotics in agriculture and human medicine is leading to pathogens becoming resistant to treatment,” Kiess explained.

“Because of this, the industry has decided that they want to look at alternatives to antibiotics so that they can ensure to consumers that their products are safe.”

What makes the lab unique

The facility features six individual rooms designed for battery cage and floor pen trials, a research lab where scientists can culture and study pathogens, separate screening rooms complete with sinks and sanitation stations, an autoclave and restroom and shower facilities.

Each room is fitted with a separate HEPA-filtered air handling system, which was one of the biggest challenges in designing and building the facility, Kiess said.

“To make sure that every room has the same airflow going in and coming out and that nothing is escaping out the back end was very challenging,” he explained.

Construction on the laboratory began more than five years ago, with the first trial starting in September 2020.

“I really think that facilities like the one that we have built are not as accessible to the poultry industry as what they probably should be. The reason for that, primarily, is due to the expense in building facilities like this, but the outcomes from the research that will be able to be conducted in the long run will be worth it because it will help the poultry industry,” Kiess concluded.

Like what you just read? Sign up now for free to receive the Poultry Future Newsletter.