The science behind cultured meat production is advancing every day, resulting in a product that closely resembles the taste, texture and appearance of chicken, beef, pork and other meats.

Advocates of cultured meat say that the process is more efficient, flexible and consistent than traditional agriculture and there is a growing interest in and openness in trying cultured meat among consumers.

“There are four major components that are used to produce structures for pieces of meat: a cell line, a bioreactor, growth medium and a scaffold,” explained Eric Jenkusky, CEO & Co-Founder, Matrix Meats, a startup which designs custom scaffolding that cultured meat companies can use to grow cell lines with.

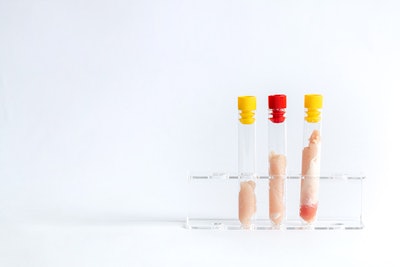

Cultured meat is made with real animal cells that are grown with the help of a culture medium in a stainless-steel tank known as a bioreactor.

Why scaffolding is important

Scaffolding plays a crucial role in cultured meat production. Without it, cultured meat would have a jelly-like consistency and lack the texture seen with traditional animal proteins.

“When trying to produce a structured piece of meat, you want to be able to create myotubes and alignment of the fibers. If you’ve ever eaten chicken and you want to make a pulled chicken or a chicken salad sandwich, you can see all of the strands of the muscle fibers as you pull it apart with a fork. That’s exactly what this technology does. It allows, for example, a chicken breast to grow so it looks like the same chicken breast that grows inside of a live chicken,” Jenkusky said.

Texture is important to consumers. Sales of plant-based proteins, another meat alternative, soared in recent years after manufacturers used chemistry-based approaches and other techniques to better replicate the flavor and texture of real meat.

Options for customization

Nanofiber scaffolding is fully customizable, says Jenkusky.

“What that means is that we’re able to control fiber alignment, fiber diameter and fiber philosophies and we’re able to input various compounds such as vitamins, minerals and flavors,” he added.

“We can also control, most importantly, the degradation rate of the scaffolding, so we can make the scaffolding so it doesn’t degrade at all or so that, after so many days or weeks, the scaffold is completely consumed as a potential source of growth to help the cells grow.”

Like what you just read? Sign up now for free to receive the Poultry Future Newsletter.