The integration of virtual and augmented reality between humans and automation could help minimize the amount of manual handling required in poultry processing.

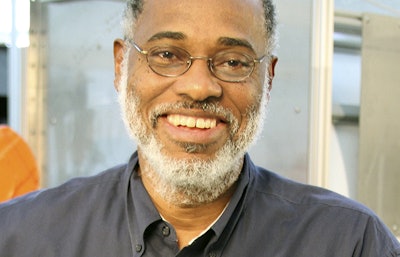

“Our idea is to seamless connect people and machines so they can operate collaboratively to address a lot of the labor and production issues in food manufacturing,” Dr. Wayne Daley, advisor to the Agricultural Technology Research Program, Georgia Tech Research Institute, explained during the fourth webinar in the Poultry Tech Webinar Series.

“We think that technology is now in a position to enable us to do that.”

Cobots to the rescue

Experts hope that robots and other forms of automation will one day be able to augment human labor. The poultry processing industry requires a lot of manual handling and repetitive motions, something that automation is very good at.

However, current automated and robotic technologies still struggle with the decision-making required to accommodate the variability of product size found in poultry and meat processing.

“What we’re trying to do is extend the ability of the available workforce through virtual reality systems,” said Daley. “You’d have the robots doing what they do well, which is mundane, repetitive things, and people doing what they do, which is to handle the unusual cases.”

Collaborative robots, also known as cobots, are designed to work safely alongside human workers. Typically, the robot is responsible for any repetitive task, freeing up the human worker to perform more complex, thought-intensive tasks.

In addition, cobots could help extend the ability of the available workforce and provide continual training for employees.

How it works

Daley envisions a man-machine collaboration to automate poultry processing

The human worker will wear virtual reality goggles that uses sensors to create a real time image of the processing line, giving them the ability to control a robot in real time to load machines and manipulate product.

“Typically, operations require sensing, perception, planning and then execution. We anticipate that people will help with the sensing and perception parts,” Daley said.

Virtual reality enables the remote operation of robots, which means that the worker no longer must perform repetitive tasks in harsh environments. In addition, one of the largest benefits of the virtual reality component is that it allows for new protocols to be tested in a virtual space before being implemented in the real world.

Daley and his team are currently in the process of working with an industrial robot manufacturer to create a prototype. They hope to begin commercial tests of the virtual reality and cobot system by the summer of 2022.

What’s coming next

For more on the technologies set to advance the poultry industry, join industry-changing innovators, researchers, entrepreneurs, technology experts, investors and leading poultry producers at the Poultry Tech Webinar Series, scheduled for November 2, 4, 10, 11, 17, 30 and December 2.

During the webinar series, industry experts will preview what’s coming next – from prospective solutions to developing technology – for the poultry industry.

This webinar series is proudly sponsored by: Arm & Hammer, Aviagen, Baader, Boehringer Ingelheim, Cargill, Ceva, Chore-Time, Cobb, Evonik, Marel, Phibro Animal Health, Staubli, and Zoetis.

Visit our website for more details on the webinar series, topics and speakers.

Register for free today and join us for a glimpse at the future of the poultry industry.