Controlling Salmonella using pre-harvest interventions requires a comprehensive, collaborative approach from integrated poultry companies and independent growers including vaccination, feed supplements and best practices on the farm.

In October 2021, the United States Department of Agriculture (USDA) announced its plans on overhauling how it approaches Salmonella. The proposed reform will likely cover pre-harvest controls to reduce Salmonella contamination coming into the plant. The new Healthy People 2030 goals are expected to drive up pre-harvest intervention use this decade.

Dr. Mindy Brashears, the former USDA deputy under secretary for food safety with the Food Safety and Inspection Service (FSIS), said this transition will be complex and could test the limits of the agency’s jurisdiction concerning the regulation of pre-harvest actions. The agency has no authority on the farm.

Brashears, now a distinguished professor at Texas Tech University, said there is acknowledgement that a transition will take time. It will require the industry and regulators to cooperate and create standards based on science and the practical realities of chicken rearing and processing.

Salmonella

Although the industry is constantly reducing Salmonella in poultry products, more than 1 million illnesses occur annually in the U.S. due to the pathogen. More than 23% of those are estimated to be attributed to chicken and turkey consumption.

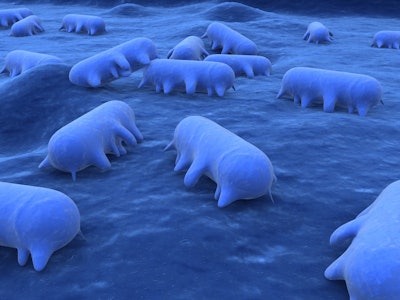

Salmonella is spread by pests and other birds, and can be inherent on a farm. Once a bird is infected, Salmonella colonizes its intestinal tract. When a bird with a high Salmonella load is processed, there is a potential for products to be contaminated.

The bacteria’s potential to create human illness depends on the serotype detected. The serovars Enteritidis, Typhimurium, Heidelberg and Infantis are most likely to cause foodborne illness.

Pre-harvest interventions

Generally, a pre-harvest intervention is any technology used on the farm, or at some point prior to processing, either individually or collectively reducing the Salmonella burden heading into the processing plant.

The U.S. poultry industry utilizes a combination of vaccinations against Salmonella, feed additives reducing the Salmonella load in live birds and best practices on the farm and during transport to reduce the Salmonella challenge.

Dr. Douglas Fulnechek, a senior public health veterinarian for poultry at Zoetis Inc., said the responsibility falls on the integrator to produce Salmonella-free birds in the hatchery and direct growers on the best practices to reduce Salmonella.

In the past, Salmonella control was considered a processing issue rather than one for live production. Fulnechek and Brashears said this attitude changed after the FSIS implemented the process control system known as hazard analysis critical control point (HACCP) in 1996. Since then, integrators increased their focus on keeping Salmonella from entering the plant.

Vaccination

The most common intervention is vaccination of broiler breeder birds.

Fulnechek said an integrator may vaccinate broiler breeder flocks as many as five times. First, with a live vaccine at a day of age, then a live vaccine booster about two weeks later. As many as three additional killed vaccines are applied while the bird is still in the pullet or poult stage of life.

Killed vaccines could be a mix of commercial Salmonella vaccines, or an autogenous vaccine. An autogenous vaccine is a made by developing a vaccine from a sample of the Salmonella present in the environment. Development of autogenous vaccines can take years.

Dr. Dianna Bourassa, an assistant professor and extension specialist in poultry processing at Auburn University, said research shows vaccination of broiler breeder birds reduces Salmonella prevalence in live birds downstream, in the processing plant and in the poultry house.

A broiler bird can receive a live vaccine at one day of age and at 14 days of age. Turkeys may receive additional vaccinations due to their longer lives, Fulnechek said.

Bourassa said routine vaccination of all broiler birds is uncommon because of its potential to increase the overall Salmonella load of the flock. Some research shows routine vaccination is effective in reducing Salmonella entering the processing plant, but there is a lack of proof that the method can reduce Salmonella prevalence on intact and ground final products.

Dr. Rick Phillips, director of key account veterinarians for poultry at Boehringer Ingelheim Animal Health USA Inc., said few integrators use Salmonella vaccines in broilers due to the perceived poor return on investment.

A new policy, she said, will hopefully acknowledge this issue and correct it by assessing the products for the virulence of the serovar detected rather than for the total number of the bacteria.

Feed additives

Feed additives are used to reduce the colonization of the bird’s intestinal tract and therefore the Salmonella load presented at the processing plant.

Dr. Ken Macklin, an extension specialist and professor at Auburn University, said the most used feed additives for breeders and broilers are mannan oligosaccharides, phytogenic compounds and other prebiotics and probiotics.

The goal of the products is to foster a microbiome free of Salmonella. As for effectiveness, Macklin said he’s “worked with some that do well but a lot that really don’t.” Additives are a backup to vaccination which are used when there are issues with Salmonella overloading the plant.

Phillips said the most used feed additives for Salmonella control in the U.S. are probiotics and botanicals. Other products, like formalin and/or organic acid potentiated based products, and high level organic acids, are added to the ration to reduce Salmonella in the feed.

The use of additives is an issue for integrators since they add cost and potentially cut into an already small profit. Dr. Bill Potter, Elanco Animal Health’s food safety technical advisor, said some probiotics deliver more benefit than driving down Salmonella populations. By improving the overall health of the gut, the bird performs better in terms of feed conversion or, for breeders, egg production. He called it a food safety benefit with an economic payback.

Best practices

The area of pre-harvest Salmonella control commonly called best practices is the collective actions of hatching and breeding, live operations and transportation to maintain a clean and Salmonella-free environment.

Brashears said the mission is to keep a clean environment in the hatchery, the house, during transport and lairage at the processing plant. This means keeping water clean, litter as fresh as possible and the holding pens and trucks clean.

Phillips said the primary sources of Salmonella are birds contaminated by the parents and subsequently the hatchery. Feed is as a potential source, too. Integrators are now considering feed intervention strategies.

Specific actions growers can take while the birds are in the house, Fulnechek said, include, controlling the population of rodents and other pests, like darkling beetles, which bring Salmonella into the house and transmit the bacteria from flock to flock. Additionally, he said growers should closely monitor ventilation to maintain a dry litter inhospitable to microbes like Salmonella.

Growers and integrators must also coordinate on feed and water withdrawal plans to reduce the amount of digestive tract contents potentially contaminating birds before and after slaughter, he said.

In between flocks, Macklin said, growers should windrow compost litter. This practice is proven to reduce Salmonella levels in litter. A longer down time in between flocks of greater than 14 days will knock down or eliminate Salmonella. Longer down times lead to better results.

As for integrators, Potter said, one method gaining popularity is analyzing the Salmonella burden in the houses and sampling to determine which serovars of Salmonella are present to target them specifically with vaccines and other strategies.

“A poultry company can use vaccines to reduce vertical transmission from breeders, and also to stimulate early immunity and provide competitive exclusion in meat birds, while using probiotics to reduce pathogen binding in the intestine, as well as water and litter acidifiers as pathogen antagonists,” Potter said, “It takes a number of interventions at preharvest for optimal pathogen reduction.”