Managing Salmonella risk is a complex task for stakeholders all along the poultry farm-to-fork supply and processing continuum. Despite decades of technology development and regulatory oversight, Salmonella continues to impact the global poultry industry and its consumers. In recent years, new outbreaks, along with new concepts for managing Salmonella risk, have reignited an interest in novel preharvest intervention technologies, particularly those that may be applied routinely via feed or water. While generally and broadly categorized as “feed additives” promoting health and performance, some of these products, which vary greatly in composition and mode of action, can also contribute to food safety programs. This article will highlight some of the challenges associated with Salmonella and will introduce the concept of postbiotics as a preharvest intervention technology, based on a case study to report findings from a commercial evaluation.

Managing Salmonella risk - the purpose of intervention

While we anxiously wait, a silver bullet against Salmonella has yet to be identified. In the meantime, managing Salmonella risk continues to require a comprehensive plan with critical control points managed by multiple stakeholders. Epidemiological concepts teach us that intervening against an agent such as Salmonella requires disruption of the host-agent-environment triad. For the poultry industry, this opportunity begins in live production operations. From breeding stock to production populations, biosecurity, sanitation, and good farm management practices remain key foundational prerequisites to prevent introduction of Salmonella into the environment from sources such as litter, feed, water, insects, pests, and personnel, among other inputs. Nonetheless, it occurs, and once Salmonella enters an environment it can be extremely challenging to remove, thereby presenting the risk of exposure and colonization to naïve birds and commencing the dynamic transmission cycle.

Historically, vaccination programs utilizing attenuated Salmonella strains have been a significant preharvest intervention strategy; however, vaccination itself is not fully effective, and the protection offered can vary greatly for individuals over time. During rearing of poultry populations, several physiological or disease challenges can occur and, in combination with a lingering environmental exposure to Salmonella, such events can increase the prevalence and loads of Salmonella within a population. Those affected individuals then shed the organism back into the environment. This cyclical nature of transmission can therefore increase the overall burden of Salmonella and present increased challenges to subsequent population placements as well as create undue pressure on downstream controls, such as those microbial interventions, both physical and chemical, utilized in processing plants. Therefore, in addition to vaccination, preharvest intervention technologies that can be continuously co-administered through feed or water and throughout the life-cycle may be an additional hurdle to prevent colonization and disrupt the otherwise perpetual transmission cycle.

What are postbiotics and can they promote health and production while also serving as a preharvest intervention against Salmonella?

As recently defined by the International Scientific Association of Probiotics and Prebiotics (ISAPP), a postbiotic is, “a preparation of inanimate microorganisms and/or their components that confer a health benefit upon the host” (7). Similarly described by Wegh and colleagues, postbiotics are, “the bioactive compounds resulting from fermentation processes by food-grade microorganisms”(8). Postbiotics, therefore, are innately distinct from prebiotics, probiotics, synbiotics, live yeast, and other similar microbially derived technologies in the feed additive category. Specifically, the production of these additives that are rich in host beneficial bioactive compounds is achieved under proprietary production conditions ex vivo. These postbiotics can then be fed or administered to the animal, thereby delivering substances that result in direct health benefits, as opposed to relying on delivery of viable organisms through milling processes, consumption by host, and establishment in the gut to produce similar outcomes. Diamond V’s Original XPC® is a leading example of a true postbiotic product derived via proprietary fermentation with Saccharomyces cerevisiae. During production, after a preliminary liquid fermentation, the primary fermentation product is transferred to a carrier matrix which undergoes secondary solid-state fermentation and controlled drying, ultimately producing a fine, shelf-stable powder that is easily included into a feed formulation.

As noted, a postbiotic is expected to directly deliver health benefits to the host. Indeed, a body of scientific literature has been published based on studies evaluating the effects of Original XPC on avian health and immunity in addition to production performance. Many benefits have been replicated and documented in the literature for many other animal species as well. In recent years, with the increased interest in preharvest Salmonella control, Diamond V has conducted a body of work investigating the potential additional capacity of its postbiotic products to function as in-feed preharvest interventions against Salmonella, while simultaneously imparting health and production benefits. For example, research conducted at the University of Arkansas has utilized donor microbiomes from cecal contents of commercial poultry and, in the absence of an immune system, repeatedly demonstrated reduced propagation of Salmonella in vitro when the microbiome is adapted to the postbiotic as compared to a control (1, 3, 6). This has been paralleled with observed increases in volatile fatty acid production, which is a well-established fuel for enterocytes and co-contributor to combat gut colonization by pathogens such as Salmonella. Given these promising concurrent observations, several controlled challenge and real-world commercial research projects have since evaluated the Original XPC postbiotic’s ability to reduce Salmonella in vivo. Following is an example case study with a commercial broiler company in the United States.

Commercial Evaluation – A Case study for Salmonella reduction in commercial broilers. Do postbiotics work?

A commercial broiler integrator in the United States collaborated with Diamond V to evaluate inclusion of Original XPC (XPC) into their broiler diet formulation, subsequently measuring Salmonella prevalence and load in the ceca of birds on feed at harvest, as well as their carcasses during processing at rehang. As with all real-world operational evaluations of new products and technologies, the study design determined must have minimal impact to ongoing operations. In this case, a study design was determined consisting of five farms wherein individual flocks within one house per farm would be sampled prior to XPC inclusion as a baseline control. Subsequently, XPC was included in the diets of these birds at the recommended inclusion rate of 1.25 kg/tonne (2.5 lb/ton). At market age, each flock was sampled at processing by collecting 60 ceca samples and 30 carcass rinse samples. The collected samples, placed at 2-8°C, were immediately shipped via overnight carrier to an ISO 17025 accredited third-party commercial laboratory. Upon receipt, the laboratory processed these ceca and rinse samples for detection of Salmonella according to USDA FSIS MLG 4.10. Prior to incubation, sample aliquots were set apart for serial dilution and direct plate enumeration of Salmonella. Reported analytical data outcomes were received by Diamond V and analyzed in SAS v 9.4 with treatment as the main effect and farm as a random effect.

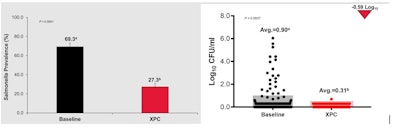

Cecal Salmonella prevalence (% positive samples from flocks within each sampling) was significantly reduced in the XPC-fed cohort of flocks sampled (7.3%) as compared to the flocks sampled in the baseline (38.1%). When comparing the mean load of Salmonella within the positive ceca, the XPC ceca (0.40 Log10 CFU/g) were approximately 0.65 Log10 lower than baseline (1.05 Log10 CFU/g) (Figure 1). Taken together, these analytical observations indicate that fewer Salmonella-positive birds were going to harvest; those that were Salmonella positive carried reduced mean Salmonella loads when XPC was included.

Figure 1: Ceca Sample Results - Prevalence and Load

Notably, the reduction observed in the ceca was concurrent with the carcass testing outcomes. Of carcasses sampled to establish the baseline, 69.3% were Salmonella positive as compared to only 27.3% observed from the cohort of flocks fed XPC, reflecting an approximate 60% improvement. Moreover, a significant reduction in mean carcass rinse Salmonella loads were also observed for XPC (0.31 Log10 CFU/mL) compared to carcasses sampled for analysis to ascertain the baseline (0.90 Log10 CFU/mL)

Figure 2: Carcass Rinse Results - Prevalence and Load

One observation worth noting was that approximately 48% of ceca and 25.8% of carcasses during the baseline sampling had a Salmonella load exceeding 3.0 Log10 whereas no ceca or carcasses during the XPC sampling exceeded this threshold, which may provide insight into the challenge burden faced by downstream post-harvest interventions in-plant. Specifically, as a concept often discussed in food safety circles, the frequency of highly contaminated individuals and carcasses entering a facility may be associated with observed “event days,” wherein process controls fail leading to costly losses in final product disposition. If this premise holds true, then reducing the frequency of such highly contaminated individuals and carcasses is an important consideration, one that is perhaps more important than simply reducing the number of positive individuals alone.

The case study presented herein is one example of how an in-feed preharvest intervention, like the Diamond V Original XPC postbiotic, may be evaluated in a commercial operation (4). There are many other design possibilities for a real-world commercial trial, each with unique benefits and limitations. While this study captured farm and house diversity, a limitation could be the time effect between baseline and treatment sample collections. Other potential study designs, such as evaluating dietary treatments in parallel, can present complications to commercial operations and, thus, successful trial execution. A highly functional product should demonstrate benefit under various research and trial designs. The observations associated with inclusion of Original XPC postbiotic in this case study align with similar outcomes reported in a variety of both published in vitro and in vivo experimental Salmonella challenges where this product was evaluated, indicating a building body of evidence supporting the postbiotic’s additional functionality as a preharvest Salmonella intervention (1-6).

Where do we go from here?

Complex challenges remain for our industry in the years ahead requiring continued investment in research and technology development. Recent advances in diagnostic and analytical tools are increasingly contributing to the promise of future real-time monitoring, such as rapidly estimating Salmonella load in various sample types or focusing on specific serovars of concern. Such developments may provide an opportunity to assess interventions more accurately, monitor flocks in real-time, and aid in determining risk-based harvesting and processing strategies. There is, however, still no silver bullet. Rather, effective Salmonella management strategies will continue to require comprehensive, multi-hurdle controls implemented across the production continuum. Preharvest interventions in feed must maintain or enhance performance and health, be easily distributed, remain stable in the ration, be willingly consumed by the population, and have a cost neutral or positive return on investment. For any such products, ultimately, their effect on minimizing preharvest Salmonella burden should be repeatedly demonstrated over time under various conditions. With a significant body of published evidence demonstrating performance and health benefits, postbiotics such as Original XPC may be an additional preharvest intervention tool contributing to a comprehensive food safety strategy.