What is Biogas and what advantages can it bring to poultry production systems?

Brand Insights from Evonik

In 2021, the U.S. poultry inventory surpassed 9.7 billion birds, including laying hens, broilers, and turkeys (USDA, 2022). Based on the total chicken meat and egg production, and the average number of birds per house (USDA, 2010 and 2022), it is estimated that there are 65,000 broiler houses and nearly 3,000 hen houses. Poultry species are very efficient in converting nutrients into meat and egg for human consumption. Evonik Animal Nutrition has helped poultry producers for decades to formulate diets that increase nutrient utilization and therefore, to reduce waste and improve sustainability. However, poultry species like any other animal, still generate manure. Throughout their lifecycle, the manure production of broilers, laying hens, broiler breeders, and replacement pullets is approximately 2.5, 20-30, 44, and 8 lbs per bird, respectively (Ritz and Merka, 2013). Regarding its composition, it contains approximately 75% moisture, 3-5% nitrogen, 1.5-3.5% phosphorus, 1.5-3% potassium, and considerable amounts of valuable minerals like calcium, magnesium, and sulfur (Chastain et al., 2001). Therefore, it is not a surprise that poultry manure is largely used as a fertilizer for crops. Despite being shown as a good alternative for synthetic fertilizers due to their lower cost, the direct application of untreated poultry manure to the field has its drawbacks.

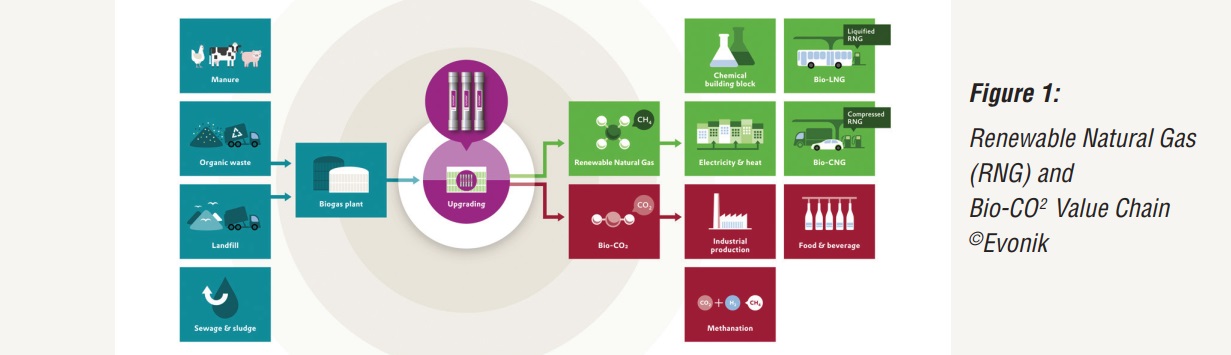

For instance, this practice is often associated with bad smell, surface, and groundwater pollution because of nutrient leaching, and emissions of ammonia (NH3), methane (CH4), and nitrous oxide (N2O) (Dunkley, 2014). Alternatively, poultry manure could have a greater economic and environmental value if the organic matter component is utilized for biogas production and the resulting inorganic matter (minerals) material as crop fertilizer. Biogas and Renewable Natural Gas (RNG) are eco-friendly energy sources, that are becoming increasingly important as part of today’s energy supply. Biogas consists of a mixture of carbon dioxide (CO2) and methane (CH4), that can be used to directly generate power or heat, or used as fuel, providing a high energy yield per square foot of land containing manure.

Biogas plants are built near poultry farms and the manure is transported from the farms to the biogas plant. The material is stirred, mixed, hydrolyzed, and then conveyed to ferment into biogas in an anaerobic tank. The biogas can be further refined to increase its energy yield. By separating the CO2 from the biogas, it is possible to achieve a highly pure RNG that meets the state standard of natural gas, containing higher than 96% CH4(Figure 1).

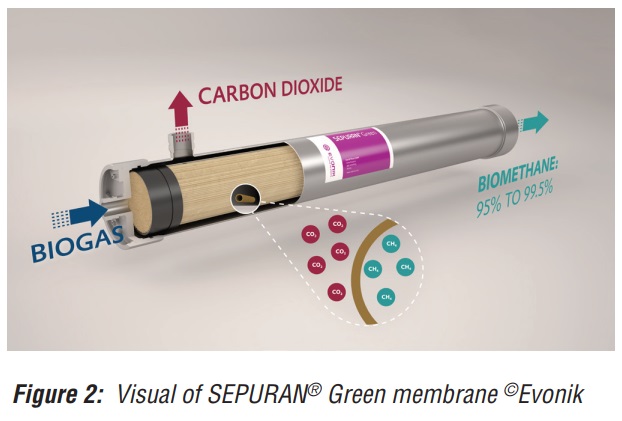

Evonik Industries has the technology that increases the efficiency and profitability of biogas plants. It consists of a bundle of extremely selective membranes made up of multiple high-performance cylindrical polymer fibers with temperature and pressure resistance. These hollow fiber membrane modules, called SEPURAN® Green, boost the separation capacity effectively between CH4 and CO2. The gas separation membrane SEPURAN®

Green works on the principle of selective permeation through a membrane surface. The driving force for the permeation of the gas through the membrane is the difference between the partial pressures of the gas on the interior of the hollow fiber and the exterior side. In the upgrading process, CO2 in the biogas permeates through the membrane, while the CH4 stays inside the membrane (Figure 2). SEPURAN® membrane technology has been proven in the field for almost 10 years, with more than 800 references worldwide and nearing 100 references in the U.S. serving industries like swine farms, landfill waste, and wastewater treatment plants, among others.

Read the full article in the December 2022 issue of WATTPoultry USA.