In a new attempt to reduce the impact modern commercial farming has on the environment, an innovative young Danish architect has come up with a vision of carbon-neutral pig farming that could pave the way for decoupling pig production from the agricultural landscape.

It may also help the Danish pig industry maintain its international reputation as a world leader in the generation and use of renewable energy to combat global warming and protect the environment.

Sustainable pig farming

Pushing the boundaries of sustainable farming beyond the dreams of many producers, Nee Rentz-Petersen’s doctorate project, which has been dubbed “Pig City”, aims to reduce CO2 emissions and make pig farming sustainable and odour free, with the added bonus of quality tomato production. She has teamed up with Danish pig farmer Søren Hansen to turn her dream into reality within the next two years.

Her design was one of the entries in a recent contest for architectural buildings of the future, sponsored by the Danish financial institution, Realdania, and supported by the newly formed Danish Agriculture & Food Council.

Speaking in Copenhagen recently, Rentz-Petersen pointed out that architects had not done much about changing the design of farm animal housing for several years, in spite of the recent advances in building and today’s concerns about the environment and animal welfare.

“There are many new techniques available now to help adapt buildings so that they can benefit the environment, by reducing energy consumption and improving animal welfare,” says Rentz-Petersen. “I have used some of them in my design for sustainable and odour-free pig farming, with a field of tomatoes on top of it.”

“I hope this will help reduce the environmental impact of commercial farming and keep energy inside, with all the heat and power recycled and re-used,” she says. “I also hope that this new building design will enable farmers to be proud of their high-tech, commercial production – and allow pig farmers to operate nearer to their urban marketplaces.”

Pigs and tomatoes

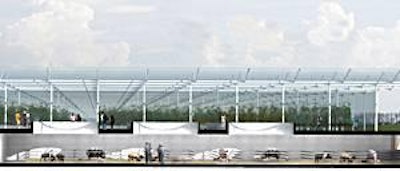

The 26,000-square-metre, 300-metre long, two-storey building will house a pig unit under what Rentz-Petersen described as “an enclosed field of tomatoes”. The self-contained pig unit will incorporate its own abattoir to slaughter 380 pigs a week on site, as well as a heat exchange system and an anaerobic digestion plant.

The development will be sited on the side of a gravel pit on a farm just south of Aarhus and visitors will arrive in a large covered courtyard at Level one – the greenhouse level. There will be nine circular skylights in the floor of the courtyard to allow the visitors to see the pig farm, which will produce about 20,000 finishers a year.

Waste from the integrated meat production unit and the slurry from the pigs, as well as waste fibre material from the greenhouse, will be used to generate biogas — and hence electricity and heat — for both greenhouse and pig production in the anaerobic digester.

In addition, the by-products of biogas production will be further processed to provide water (for crop irrigation) and dry matter (for fertiliser).

Meanwhile, the soil and plant roots in the greenhouse on top of the pig building will provide a “natural” filter to absorb the ammonia and odour vapours caused by pig production.

Urban pig production

The trend-setting young architect pointed out that all the surplus energy generated by the biogas system could be used locally (heating and lighting), as well as to reduce energy costs for both the pig farm and the tomato producer.

“Currently, the profitability of greenhouse production in Northern Europe is very dependent on energy prices,” she said. “A stable supply of sustainable energy at a controlled cost will help re-establish the profitability of this type of agriculture.”

In addition, she said that if the self-contained unit proved to be successful, other ones could be built much closer to urban settlements, perhaps in industrial centres that had good road access, further decoupling pig farming from the agricultural landscape.

Both she and Hansen are so enthusiastic about this project that they say that when it is finished it will be open to the general public, so that they can see all the many facets of food production at close hand.

“Pig City will operate on a birth-to-slaughtering principle, which means the pigs won’t have to be transported anywhere, so there is no risk of pigs becoming stressed before slaughter,” says Hansen.

He added that the animal welfare benefits of the novel unit included a loose housing system, as well as larger stalls and straw for the sows during the period up to farrowing.

Other benefits include:

-

The removal of unpleasant odours from the housing units

-

No environmental discharge of ammonia and other fertilisers via the exhaust systems

-

Surplus energy and heat generated by the biogas system can be used directly on site, instead of wasted

-

No need to spread manure on fields

As far as production in the greenhouse was concerned, Hansen said the two-in-one farm would mean reduced energy expenses and no need to bring in extra fertiliser.

“We haven’t got all the financing in place yet, but we are in the process of drawing up a budget and getting approval from the authorities,” says Hansen. “If everything falls into place, we hope to get started on the building in the spring of 2010, so the first pigs can be ready in 2012.”

Rentz-Petersen, who is coordinating the project, said: “I hope this will demonstrate how agricultural production can be combined with respect for animals, humans and the environment and greater profitability.”

(1).jpg?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)