North Americans reading about H5N1 in the county of Suffolk in United Kingdom (UK) and with fathers or grandfathers who served with the USAAF (United States Army Air Forces) in the Second World War may well have heard some familiar town names.

The Bernard Matthews turkey farm at Holton – where 160,000 birds were culled in early February – is on the old Holton airfield (also called Halesworth). It housed a number of famous USAAF units, including 489 Bomber Group flying the B-24 Liberators, which were more versatile but less rugged than the B-17, dubbed the ‘Flying Fortress’.

But fortress was the last thing that Bernard Matthews’ turkey farm proved to be when the highly pathogenic H5N1 strain of the avian influenza (AI) virus struck at the end of January.

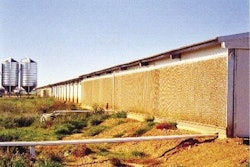

The old Holton airfield still houses hangar-type buildings but these now contain turkeys rather than military aircraft. Aerial photographs show 22 turkey rearing sheds are actually built along the old airfield runway. Right next door and just 500 metres away is a Bernard Matthews turkey processing plant comprising slaughterhouse, cold store, cutting and packing plant for fresh turkey meat and a factory for further meat processing into turkey products such as breaded escalopes and turkey burgers.

Having poultry farms and factories on the same site makes good sense, when faced with highly infectious and virulent diseases like H5N1. There are moves in South-east Asian countries to consolidate and integrate rearing, slaughtering and processing onto single sites to minimise transport of live birds and fresh meat, thus minimising risk of disease spread.

The same should have been true for Bernard Matthews at Holton when processing turkeys reared there and others from farms throughout the UK where until now there was no history of H5N1 in poultry.

But Bernard Matthews is a multi-national company trucking in fresh poultrymeat to Holton from all over Europe including Hungary for further processing. It appears to have picked up H5N1 contamination in Hungary following an outbreak there in January 2007 and brought it into the UK although the mode of entry has not yet been established.

If biosecurity measures around the rearing sheds and the processing plant had been tight, this trade would not have come to light. But turkey off-cuts and waste left uncovered outside the factory were apparently picked up by scavenging birds including gulls and carried onto roofs of rearing sheds. These had holes big enough to let in small birds and rodents, let alone rain water running over wild bird faeces and waste meat on the surface of shed roofs.

The moral from this tale is that poultry production and processing operations consolidated on one site are fine as long as the level of biosecurity is ‘watertight’ across the whole site.