The business outlook among poultry processors at the 2011 International Poultry Expo was surprisingly upbeat considering a turbulent economic picture. One of the reasons may be the availability of technologies that promise to cut costs and/or improve margins on poultry products.

Not that anything fully answers $7 a bushel corn and a potential oversupply of poultry in 2011, but poultry processors at least have options that help address their economic predicament.

Vendors see optimism among poultry processors

A WATT PoultryUSA survey of some poultry processing equipment exhibitors at IPE indicates that not only is there still pent-up demand in the wake of the last recession, but processors believe they need to invest in equipment for greater efficiency and to allow them to upgrade their poultry products for higher margins. They seem to feel that this is a big part of the answer to be able to make it through tough economics forecast in 2011.

Heath Jarrett of Meyn said, “The industry tone at the IPE was unusual. The attitude on the part of many industry people there was that it is going to be tough year, because corn and soybean prices are up. That was coupled with gas prices being up and forecast to continue to rise. But there was an underlying attitude that this is going to be the new economic norm and the industry has to get prepared for it and adjust.”

Jon Hocker of JBT FoodTech agreed by saying, “There was an unusual enthusiasm on the part of processors in spite of the economic obstacles they are facing. But that may be, in part, because technologies are available to help answers those challenges. Certainly, with grain prices going up and possibly staying high in cost, processors are trying to figure out how to adapt to that new reality.”

Challenges facing poultry processors

According to the processing equipment vendors surveyed, key challenges facing poultry processors include the following:

- Rising grain and energy costs

- Labor scarcity

- Food safety

- Meeting sustainability goals

- Need for greater efficiency and overall cost reduction

- Adding value, and margins, through product convenience and quality

- Meeting changing market demands with flexibility in processes

Jeff Ray of Marel-Stork said, “Processors are responding to the challenges by finding ways to get more revenue per pound on the products they are selling.”

One of the means of cost reduction and value addition continues to be product portioning. Vendors like Marel-Stork, JBT FoodTech, Meyn and others exhibited portioning products at the 2011 IPE.

Portioning options continue to evolve

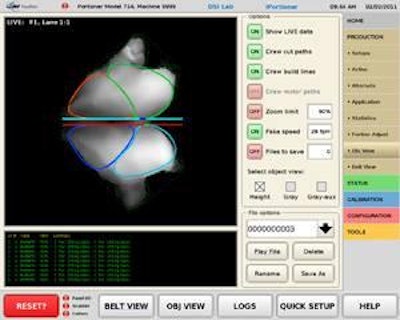

JBT FoodTech demonstrated the DSI Adaptive 3D Portioning system, which combines the DSI Adaptive Slicer and DSI Waterjet Portioner. The system offers the ability to create two, four, six, or more, portions per butterfly.

The Adaptive 3D Portioning system, which uses cameras to locate fat and determine shape, thickness, and weight, produces portions, nuggets or chunks, fat-free product and strips. Computer-positioned high-pressure waterjets cut shapes that make each piece as valuable as possible.

“This is the end envisioned five years ago, when we first introduced waterjet portioning and started the R&D project which was aimed at an intelligent waterjet portioner communicating with an adaptive slicer. The new software in the portioner automates the positioning of the cuts on the meat, which is a big step forward. Also, new software on the adaptive slicer interacts with the portioner, which results in a lot of the new benefits,” Jon Hocker said.

The new system can deal with a large degree of variation in the size of inputs, which naturally results in a flock of broilers, according to Hocker.

“Processors don’t have to have to produce birds with perfect size butterflies, nor do the inputs have to be graded,” he said.

Capacity added to portioning systems

MP Equipment introduced the MPAdvantage MegaJet Water Cutter portioning system with eight XY cutters across two lanes of production. The system offers customizable configurations to produce strips, nuggets, filets and fat trimming. The software allows for the adjustment of the length and width of strips.

The MegaJet Water Cutter’s eight XY cutters across two lanes offers flexibility in cutting and increased capacity in a footprint similar to that of single-lane portioners, noted Blake Wikle.

MP Equipment introduced a single-lane cutter with two XY cutters and four X cutters four years ago. Mark Phillips of MP Equipment said, “We soon learned that the single-lane cutter could cut at very high speeds but there was difficulty in loading and harvesting. The new MegaJet Water Cutter has dual lanes, which makes loading and harvesting easier and more feasible. Belt speed on the lanes – from 10 to 80 feet per minute – is determined by the number of cuts to be made in the meat block, he explained.

The MegaJet Water Cutter’s features include a fully-integrated, stainless-steel, high-pressure pump and dual-touch screen controls with operator interface.

Marel-Stork introduced the dual-lane SmartSplitter which doubles the portioning capacity of the single-lane splitter. The dual-lane SmartSplitter can operate with different height settings on each lane.

Adding value to poultry meat trimmings

Another way of enhancing margins is to upgrade poultry trimmings.

Marel-Stork exhibited the Townsend RevoPortioner which uses a low-pressure process to form trimmings into product with the look and texture of a whole-muscle filet in any desired shape. The trimmings are fed into a vacuum hopper and from there into a rotary forming drum.

Gainco, a division of Bettcher Industries, introduced the Whizard TrimVac white meat recovery system, which harvests sub-tender white meat from beneath the wishbone, along with “eye” muscle lean meat that anchors the breast muscle to the breast frame as well as lean meat along the rib, keel and back.

The TrimVac system uses a high-speed rotating blade to dislodge, cut and vacuum white meat in the sub-tender area and under the wishbone. A vacuum system removes the breast trim and conveys it to a stainless-steel containment tank.

In chicken frames processed on cone lines, valuable meat is often captured in mechanical deboning machinery where the product is classified as MSC (mechanically separated chicken) and carries a low price. The value of the trimmed white meat can be up to three to four times more than the value of MSC.

Processing plants that adopt the TrimVac tool for white meat recovery experience impressive yield improvements, according to Keith Moffitt of Gainco. It is common to achieve a 0.50 - 0.75 oz. increase in yield on an 8 lb. bird – from the breast sub-tender area alone, he said.

“On a typical plant processing 1.5 million birds a week, revenues might be increased by $1.4 million assuming the value of boneless white trim is 90 cents or more a pound and the per-pound values of bony trim meat and MSC are 50 cents and 18 cents, respectively,” Moffitt said.

Flexibility in processes can save investment

Air Products exhibited the Freshline DM tunnel freezer, which allows for the cryogenic freezing of both individually quick frozen (IQF) and flat or trayed products in a single machine. This flexibility is said to offer capital savings when processing a variety of poultry items, such as diced and sliced products, wings, filets, cutlets and breaded and trayed products. It also allows poultry processors to adapt quickly to changing market demand by allowing them to switch between IQF and non-IQF products without changing equipment.

Yield, grade improvements in cut-up

Meyn showed a new precutter for the Meyn WLD whole leg deboner. The precutter automatically cuts and loosens meat around the bone on the inside of the leg before it exits the cut-up line leading to the whole leg deboner. This eliminates the need for manual cutting to loosen the meat for the whole-leg deboning process.

Also on display was the Meyn Magic automatic giblet operation, which was introduced in Europe last year and is being tested at a processing operation in North America. The Magic sweeps the giblet package from the Maestro evisceration line and automatically separates the intestinal package from the heart, liver, lungs and gizzard.

Cantrell exhibited a whole-bird splitter which is being field tested. The new splitter incorporates a strengthened tumbler and horn. Early results show a reduction in miss-splits and down grades, according to Dane Woods of Cantrell.

The Cantrell KFC Wing Cutter with Wing Stretcher, which was introduced 18 months ago, was also on display. The wing cutter solves the problem of downgrading of breasts associated with wing cuts of KFC grilled chicken, he said.

Prime Equipment showed the CTTC-2 Tender Tendon Clipper which was is the final phase of field testing at the time of the expo. The tender tendon is manually clipped on most cone lines. This machine eliminates this manual position on cone lines.

The CTTC Tender Tendon Clipper, which operates at 42 front halves per minute, improves cut consistency and A-grade tender yield, according to Mitch Staugler of Prime Equipment.

The tender tendon clipper is an add-on module for existing cone lines and requires minimal changes to the lines.

Prime Equipment also introduced the CSK-12-NW No Water Poultry Skinner, which is in the final phase of field testing in international markets.

“Many customers, especially in international markets, want to avoid having water near the product,” Staugler said. “We are also field testing this machine for the U.S. market and expect to release it for sale in early summer 2011.”

First-stage processing supports food safety, bigger birds

Morris & Associates introduced a prototype parts finishing chiller in anticipation of FSIS of salmonella testing standards expected to be proposed in regulations for the cut-up stage of processing.

A conveyor feeds the parts into the parts finishing chiller, which contains any of the approved biocides on the market. Residence time in the chiller, which is controlled by a variable speed drive, is from 15 seconds to one minute.

TopKip exhibited the Combi In-Line Air Chilling System, which is a combination of water chilling and air chilling for poultry processing facilities.

The system saves on water usage (up to 95%) and energy costs (up to 45%), according to Adrian VanderHave of TopKip. The system is said to have a high chilling efficiency, chilling product up to 50% faster than air chilling alone.

Poultry chilled with the system have excellent bacteriological characteristics, he said, and superior shelf life.

VanderHave said the system can be readily integrated into existing chilling systems.

Foodcraft exhibited the ‘548’ overhead trolley system, which increases the shackle spacing from six inches to eight inches on-center. In-plant results have shown a reduction in damage to wings, keels and rework.

Corrugated poultry boxes go waxless

International Paper introduced the recyclable ClimaShield wax-alternative, corrugated packaging technology.

“Corrugated packaging utilizing ClimaSeries technologies are recyclable and repulpable and can be sold as OCC (old corrugated containers), a win-win for our customers and the environment,” said Chad Fowler of International Paper.

Interstate Container introduced the Greencoat waxless poultry box, which is 100% recyclable, repulpable and compostable.

The Greencoat box, which is said to be easier and less expensive to glue than wax containers, reduces box room waste and runs on the same equipment as existing wax containers.

It is also “cost neutral,” according to Jeff Cormier of Interstate Container. “In today’s high commodity price market, this is very important as poultry companies want to do the right thing but can’t go into a higher-cost container,” he said.

Cook-in-the-bag packaging

Sealed Air Cryovac exhibited retail and foodservice packaging lines including Grip and Tear and Oven Ease.

Oven Ease is the Cryovac cook-in-the-bag packaging, which allows raw poultry to be cooked by the processor in a facility that otherwise handles only raw product. “The Oven Ease packaging allows for cooking in the processing plant without having to re-outfit the processing facility to meet the sanitation requirements for cooked products,” said Don Smith of Cryovac.

The Oven Ease packaging has applications in both foodservice and retail markets, but Smith said market acceptance is still small. “We think foodservice is the first market where the product will gain wider acceptance,” he said.

Smith also reported that Butterball and Perdue Farms are introducing the Grip and Tear packaging, which combines a vacuum shrink bag with the addition of an easy-open feature, across their further processed and deli product lines. This packaging eliminates the need for a knife in opening the product.

Butterball has introduced the Grip and Tear packaging in its fresh and frozen turkey products. And some marketers are now evaluating the packaging for whole broilers, he said.

Saddlepack packaging

Multivac exhibited its “saddlepack” packaging, which allows consumers to buy in larger quantities with the freedom to use some immediately and refrigerate or freeze unopened sections for later use. The technology employs an efficient and hygienic loading process made possible with horizontal thermoform packaging technology.

The processing and packaging exhibits and products reviewed in this article are only a sampling of those on display at the 2011 IPE. For listings of exhibit visit the International Show Guide. The guide can be viewed on computers and digital-enabled smart phones at www.digitalexpoguide-digital.com, and the iPhone/iPad app can be downloaded by searching for IPE Guide at the Apple App Store.