A boar stud opened this year in the north of Italy is being called Europe's most modern semen production centre for use in the artificial insemination of pigs. It is also Italy's largest, with places for 200 boars.

The owner of the stud, the Martini group, is one of the major integrated feed-to-meat companies in Italy. This family-owned business is involved in producing poultry, rabbits and beef as well as pigs. Its experience in the pig sector goes back over 30 years.

Today the company owns over 20 000 sows and contract rears 450 000 pigs to the heavy Italian slaughter weight of 165kg. It also operates a state-of-the-art slaughterhouse near Ravenna that kills and processes over 600 000 pigs per year.

Over the years there has been a natural progression in the company's pig production procedure. In the early days its farms were farrow-to-finish units, but the sites with sows were converted to weaner-producing herds when finishing on contract emerged as a popular choice. Later, as Martini moved over to multi-site production, these sow herds increased in size and became Site 1 facilities.

The pig producing network of the Martini group in 2007 runs specialist gilt rearing and service facilities. Production director Dr Marcello Marchesi remarks that "the natural and logical progression from a health and efficiency point of view" was the creation of a central boar stud to serve all the sow farms.

Isolated for biosecurity

A site for the new stud was chosen at Monte Castello Di Vibio, near Perugia in the central Italian region of Umbria. Nestling in the green Tiber valley, the site offered very good biosecurity advantages in an area with a very low pig density with the added advantage of being relatively close to the majority of the Martini sow herds.

In overall layout the stud is divided into the differentiated zones of pig housing and laboratory, with no contact between them. There are separate changing rooms and showers for the 2 sectors.

The places for the stud's 200 boars are located in slatted pens with underfloor scrapers, inside 3 buildings which are all climate controlled. These houses are linked by a passageway which leads to the collection room.

"Given the fact that Martini has 60 years of experience in producing animal feed," says Dr Marchesi, "you will not be surprised to hear that we place a particular emphasis on the correct nutrition of the boars. All them are weighed individually on a weekly basis. We then adjust the daily feeding scales to maintain each boar on a positive plane of nutrition towards achieving a pre-determined rate of weight gain. The diet we use has a high-technology specification aimed at maximising semen quality. Currently, the Martini technicians are researching the optimum growth curves on adult boars in relation to semen production."

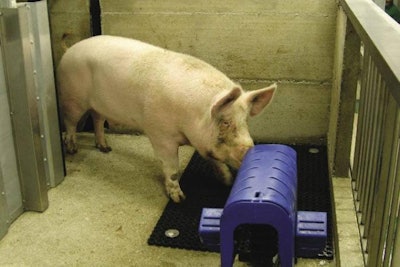

He calls the powerhouse of the stud its semen collection area, which consists of a central pit surrounded by 6 collection pens. Each of the pens is served in turn by 4 'warm-up' boxes. The operators observe that the normal behaviour by the boar is to defaecate and urinate during the walk from its own pen to the 'warm-up' place, in preparation for the day's work.

Electronic identification

At the entrance to the collection pen are hydraulically-controlled doors with command buttons both in the pit and in the outside corridor. Every boar has a transponder in an ear tag which is read as he enters the pen. This information is transferred to another microchip situated in the collection beaker. Once the collection is terminated, the collection beaker is passed from the pit to the laboratory through a double heated window.

The first operation is to read the information on the collection beaker. Provided that the boar is correct and is listed on the daily collection rota, an adhesive label is printed which traces the whole process. The semen then is weighed in readiness to start an elaborate procedure of analysis.

Semen assessment at the Martini stud utilises computer assisted sperm analysis (CASA) software purchased from Minitube and known as SpermVision. In a few seconds, this standardises the evaluation and calculation criteria to give extra accuracy for judging sperm motility and concentration. At least 1000 individual spermatozoa from 7 different fields are analysed at 'line speed'. Thirteen individual measurements are made of sperm motion. The software includes an image archive of each collection for later reference.

The Monte Castello Di Vibio laboratory produces its own analytical-standard purified water which is used for the production of the diluents. Once the semen analysis is complete, the program calculates the precise amount of diluent to be pumped from the pre-heated vat. Semen doses are bottled in tubes using a MiniBSP machine which operates at 700 tubes per hour. Filled and weighed individually before being sealed, the tubes receive a label automatically to show which boar was used together with the collection date and lot number.

The next step involves a transfer of the tubes to a cooling room in which their temperature can be brought down to 16°C. Finally the doses are despatched in the stud's own delivery vans over distances of up to 300 kilometres, a national courier service being used to deliver to herds further away. Digital thermal data loggers keep a frequent check on temperature during the delivery process.

"The boars themselves are also important!" Dr Marchesi declares. "All our boars at this stud originate from PRRS-negative farms. The stud itself is PRRS-negative and blood tests are carried out on a weekly basis.

"It houses boars from 4 different genetic suppliers. This offers our producers great flexibility in meeting the changing demands of the marketplace. The worldwide trend in pig AI is towards purchasing semen from external studs. The new Martini stud enables the Italian producer to have access to first-class genetics via PRRS-negative semen, using the latest technology available today." PIGI