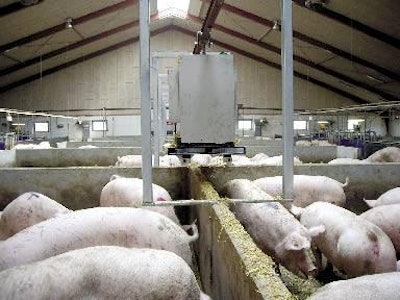

A whole raft of legislation dictates pig housing choices in Denmark, as in other countries of the European Union. Among the legal requirements that take effect up to 2015, there are specifications on floor area per pig, on the minimum flooring percentage that must be solid or drained, on showers for bigger pigs and on the use of partly-closed pen walls. Another feature of these laws is their reference to straw.

A Danish herd is required to allow its group-housed sows some access to straw or a similarly fibrous material. Since 2003 it has been an obligation also to make straw permanently accessible to weaned and growing-finishing pigs. Within another 7 years this rule will apply to all housing for all pigs. No wonder, then, that the handling of straw and "other manipulable materials" (composted bedding, wood chippings and hay are mentioned as examples) has become an issue for Denmark's producers to contemplate.

Straw bedding is already in use in many of the country's 2-climate pens for piglets and finishing pigs, meaning the type of housing in which the rest area at the rear of the pen is covered by a lid to create a micro-climate. Typically there is a layer of straw across the floor surface under the lid. Deep litter is more common in yards that hold pregnant sows in groups. Farrowing pens may have a smaller amount of straw either scattered on the floor or offered in a feeder-style container on the pen wall.

Compact bales usually are broken up by hand and distributed using a hand-cart. Tractor fork handling of big bales is seen frequently in sow yards, although the most recent installations may transport a bale through the house on a mechanical grab that travels along an overhead rail. On an 1800-sow herd near Odder in Jutland, however, mechanisation of the strawing process has gone even further. It also uses a carrier on a rail fixed above the pigs, but this now takes the form of a robotic distributor. Lengths of straw loaded into the distributor's feeder-like box are spread out to the pigs below by means of rotating wheels.

This so-called bedding robot, supplied by manufacturer Jørgen Hyldgaard, is programmed to issue fresh straw morning and afternoon every day to the unit's gestating sows in loose housing. Previously, straw was given to the sows by hand, which involved throwing it from a central gangway. This was time-consuming and it caused an uneven distribution in which only part of the bedding material landed in the intended target area of the laying area.

Worse still, it was a difficult environment for the attendant. The dusty air was often filled with the noise of fighting sows. The robotic replacement not only has saved manual labour, says herd owner Erik Stampe, it has also had a beneficial effect on animal behaviour.

Today the multiple yards of the 1000-sow gestation facility are quieter and calmer as well as being less dust-laden. Fewer fights occur among the sows and they behave as if less stressed, with only an occasional animal chewing on rails or displaying similar stereotypic behaviour.

Mr Stampe suggests another advantage for investing in the robotics. Since the installation, he observes, it has become easier to supervise the sows and pick out those requiring separation or treatment. One of the herd's attendants follows the robot around during the morning distribution. He finds that, when it spreads the straw, about 90% of the sows stand up and the rest are easy to encourage to their feet. Therefore a quick yet thorough inspection can be made of the animals in every yard.