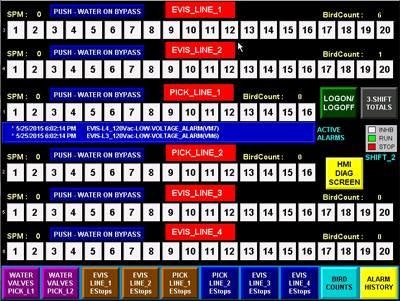

Cantrell's line monitoring control panel tracks vital information for a processing plant’s picking and evisceration overhead conveyor systems. It monitors up to 16 individual stop circuits per line for picking and evisceration overhead lines. It can check up to four evisceration lines and up to two picking lines for a total of 96 monitored points. The system can be fully customized for each individual plant’s needs. Operators can customize the names for stop stations for better accountability. The control panel tracks the total number of stops per minute and total minutes stopped, as well as the stops and total time stopped per shift. It is capable of keeping a three-shift history record, and the status screen displays which stop has been activated for every line.

The maintenance screens allow individual monitoring of inputs/outputs (I/O) on the controller. By naming each station, operators can easily identify what each output or input relates to on the plant floor. Operators are able to check outputs for blown fuses or tripped breakers.