April, 2006- What does it take to be a McDonald’s supplier? McDonald’s director of quality systems and Spence Jarnagin of Keystone Foods took up this question at an educational session at the International Poultry Expo. A packed crowd heard that it sometimes takes collaborating with competitors, occasionally requires finding unorthodox solutions and always means delivering quality.

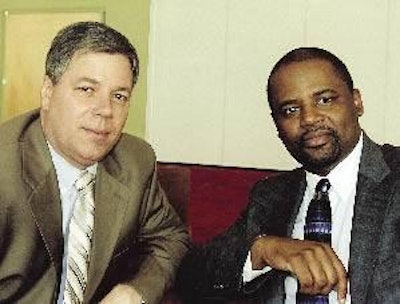

Lamont Rumbers, McDonald’s USA director of quality systems, told listeners that it takes an exceptional commitment to quality to be a McDonald’s supplier. “Consumers want to feel they can trust us,” Rumbers said. “We have a public trust all along the food production chain—from farm to table.”

For the chicken suppliers chosen by McDonald’s, it’s big business. They supply 600 million pounds of chicken in the U.S. annually or the equivalent of 5.5 million broilers a week. Today, around 30 percent of McDonald’s menu items are chicken based. That includes McNuggets, breaded sandwiches, grilled strips and salads. Just for its Chicken Select menu item, McDonald’s uses 65 million pounds of chicken. This reflects the nearly 80 percent growth recently in the chicken strips category in the QSR sector.

“Being a McDonald’s supplier means more than raising broilers and shipping them out,” Rumbers said. “A supplier for McDonald’s has to have a strategic plan. How are you as a supplier going to protect the product, improve the product? What we expect is for everybody along the chain to be able to articulate their process. Can you demonstrate how well you’re doing? We also expect suppliers to collaborate with one another. Sometimes suppliers are competitors, but inside the McDonald’s system they are not competitors,” he said.

Keystone’s Jarnagin gave an example of that collaboration that involved the launch of McDonald’s Chicken Selects. “The suppliers were delivering a product to the specifications requested, but some restaurant owners/operators had concerns about the portion sizes. People with McDonald’s, Keystone and Tyson Foods got together and chartered a plane, went to the different plants, and looked at the processes.”

Not every solution has to be highly technical, Jarnagin; explained. “One of the short-term steps we took was to buy several hundred small, plastic rulers, to hand out to restaurant operators. While we were working on the long-term fix, we put those in the restaurants. If operators weren’t sure that a portion size measured up, then they put it on the ruler. In the meantime, we used both internal and external resources, until we got it right. The restaurant operators were thrilled, and the consumers have been, too.”

Jarnagin cited another example of the ‘systems first’ approach for McDonald’s suppliers. “Right now we’re working on a project designed to simplify restaurant operations,” Jarnagin said. “We split the research work with Tyson. They are creating solutions for some menu items, and we’re working on others. Eventually, we’ll come together, pool our results and all use the same shared concepts and technologies. It’s not business as usual, but it delivers the best possible quality to the consumer in the end.”