What has been hailed as the U.K.’s largest carbon removal initiative is now firmly underway, and poultry farmers will not only be central to its success, but also directly and indirectly benefit from it.

The project will see the large-scale transformation of poultry litter, using pyrolysis to turn it into biochar, which can then be used as a slow-release fertilizer.

Sixteen hubs are planned around the Wye river, classed as one of the U.K.’s most iconic, but which has been deteriorating due to pollution, largely said to be the result of run-off due to intensive livestock farming.

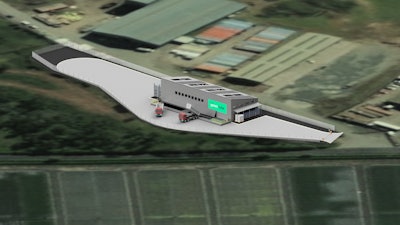

The project comprises the construction and operation of 16 pyrolysis hubs and Onnu, the company behind the project, has now bought its first plot and hopes to complete the first hub by April next year.

The eventual string of 16 hubs should bring the land-spreading of poultry manure around the Wye river to an end and sequester over 500,000 metric tons (MT) of carbon, which would otherwise have been released into the atmosphere.

Blot on the landscape?

Onnu CEO Giles Welch believes that turning poultry manure into a safe and transportable organic fertilizer is the only genuinely sustainable solution to the problems of the river Wye.

But will Onnu’s 16 hubs simply be a blot on the landscape, replacing one problem with another?

According to Welch, each hub will be no larger than a typical U.K. barn, and they will be self-sustaining units with storage located underground. There will be no discernable noise or odors, meaning that the hubs’ operation will have no negative impact on their surroundings. Each will be built only a few minutes’ drive from poultry farms to minimize traffic.

Each hub will house two pyrolysis machines able to process 10,000 MT of waste annually. Once all 16 are operational, they will be able to process 160,000 MT of poultry litter annually – sufficient to account for all of the litter produced in the Wye Valley catchment area.

Why the Wye?

The river Wye has suffered from pollution arising from run-off and other sources, leading to the formation of algal blooms and a deteriorating health status. The main pollutant causing concern, according to the U.K. Environment Agency, is phosphates, with around 73% coming from nutrients leaching from livestock manure.

Onnu’s process will capture the phosphorous and ammonia in litter. The biochar can then be spread on land without causing run-off or emitting greenhouses gases and will be only 5% the weight of the original manure, which lowers storage, transportation application requirements.

Current approaches to disposing of poultry litter are simply not fit for purpose, Welch argues, and have had a devastating impact on the local environment.

The advantage of pyrolysis, he continues, is that it is a self-sustaining process that uses the energy in the litter to dry it and heat the resulting feedstock until it decomposes into biochar. The process also locks all the carbon contained in the litter into the biochar, which serves as a carbon sink qualifying for carbon credits.

In most cases, more energy is created than is needed for the pyrolysis process, and this surplus can be provided as a green energy source to decarbonize other business operations.

Come next year, poultry farmers around the Wye valley may start to see their manure not as a problem but an asset, while for wildlife in the Wye river the future might start to become a little brighter.