Could artificial intelligence (AI), with all its promise, assist the poultry industry in addressing the challenges that it faces and raising its performance?

The global outlook for poultry products is excellent with demand driven by population growth, rising income levels, favorable trends in dietary patterns and consumer preference fostering greater demand for animal proteins. However, these opportunities are not without challenges.

Livestock producers are facing greater pressure to produce more with less and are frequently questioned about their environmental impact. The poultry sector may have the lowest emissions levels of all livestock sectors, yet it still must find ways to lower its carbon dioxide production.

Bird well being and welfare are ever more challenged and, while responsible antibiotic use has always been a mandate of the poultry sector, more consumers are demanding no antibiotics ever, necessitating better management practices and potentially compromising welfare.

The use of AI may be able to address many of these issues.

The role of artificial intelligence

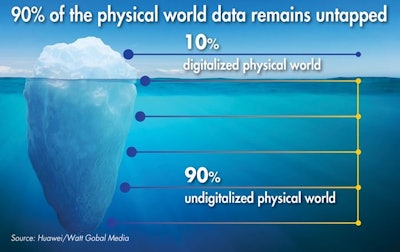

By 2050, the average farm will generate 4.1 million data points through internet of things sensors and related devices, but are we ready to make the most of this information?

Most farms still rely on pen and paper to record information and collected data must then be fed into a computer to discover what it may reveal.

The true power of AI is that its automatically collected data and in-depth analysis can allow us to immediately optimize production. Data mining is the “gold” for farmers and AI will help them to extract maximum benefit.

Machines have the ability to learn from data – the machine learning process. During supervised learning, numerous examples of what is or is not acceptable production data are provided to train the machines. This may be, for example, expected weight at 21 days for a specific line of broilers under local conditions.

Machines also have the ability to learn in an unsupervised manner where data will be categorized and trends detected without specific programming or labeling. Using resources from the cloud, huge amounts of data can be analyzed quickly, giving advance notice of a particular outcome.

Some companies are now specializing in using farm production data to predict performance. Using data from a wide range of sensors measuring bird weight, temperature, feed and water consumption, humidity, ammonia levels and many more parameters, they can predict with real time data the future performance of broilers. Their services offer producers a 14-day view into weight prediction.

AI is an excellent tool to mitigate or enhance a specific outcome as producers gain two weeks to implement corrective actions to reach the intended target weight for their birds.

On the ground

The application of AI on poultry farms is probably better known through the use of robots that can perform a number of tasks. Amongst the advantages of robots is their presence in houses 24 hours a day, seven days a week.

In breeder houses, robots are used to reduce floor egg incidence, resulting in cleaner eggs and better hatchability, and reducing the need for human intervention. In broiler houses, robots are used to stimulate bird activity, contributing to improvements in both feed conversion and average daily weight gain.

Robots offer not only higher productivity and profits but their presence can also contribute to improved health and welfare.

The most visible signs of employment of artificial intelligence on farms is in the form of robots that not only improve efficiency but also benefit bird welfare. | Courtesy Octopus Robots

Some robots will continuously scratch the litter to eliminate caking and wet spots, reducing the incidence of pododermatitis, foot burn and breast burn. Others can monitor and map ammonia, temperature and humidity levels throughout the house. This is valuable information for producers who can adjust ventilation and address any localized issue that may affect bird welfare or productivity. These corrections can prevent a localized issue from affecting the entire flock.

Layer farms have their own robots with some prototypes able to collect floor eggs while, at the same time, monitoring the environment and the health of laying hens.

Scientists are now teaching machines how to recognize any sound of distress or discomfort to aid in monitoring bird well being.

Another area with great potential for AI is its use in detecting early stage disease. AI has the potential to assist in detecting diseases during their incubation period, allowing producers to quickly prevent spread throughout a flock. AI can also help with disease diagnosis. Using AI to complement or augment the human brain - collaborative intelligence - will give us the potential to be more efficient and accurate in diagnoses.

Other areas for AI include feed formulation optimization, genetic selection and hatchery management. All segments of the poultry sector will be able to benefit from applications using AI.

Beyond the farm

The value of AI extends beyond farms, with a range of applications in poultry processing and egg packing and processing plants. AI has the potential to help address some key issues, such as painful and repetitive tasks, lack of real time processing data and the limiting speed of human interventions.

In poultry processing the use of artificial vision offers real-time yield monitoring of high-value chicken parts, allowing supervisors to immediately give feedback to employees who can address any potential deficiency.

Artificial vision also constitutes a standardized method that can be used to compare results between workers, shifts and processing plants, particularly valuable for large companies operating across multiple sites.

Artificial vision can also be combined with smart automation to optimize efficiencies; for example, where broiler parts are automatically sorted after inspection. For processors, AI allows higher processing speeds and accurate packing of premium value products, translating both into more profits and fewer customer complaints. Researchers are now looking at means to totally replace human intervention for some specific tasks considered painful or hard to achieve accurately and consistently.

The egg sector also has its fair share of applications for AI. The quality of the egg white – for instance, the absence of any trace of yolk - is important for many applications requiring optimum egg white foaming. Modern breakers operate at very high speeds, in the order of 200,000 eggs per hour or roughly 60 eggs per second, making it impossible for the human eye to detect an issue. All new equipment is equipped with artificial vision, allowing the egg processing sector to increase both the quality of its products and the efficiency of its production. For many years, this detection of external and internal defects of shell eggs was carried out by workers, therefore limiting the speed at which the egg grading machine could operate. The use of artificial vision to detect and remove defective eggs has both removed the potential for human error and now allows the grading of eggs at very high speeds, up to 255,000 eggs per hour or 70 eggs per second - a speed too fast for the human eye.

For anyone still worried about AI, let’s consider AI more as collaborative intelligence where machines augment human capacities rather than replace them.

Egg breaking is now operating at much higher speeds with higher quality results due to the adoption of artificial vision. | Vincent Guyonnet

4 poultry biostatistics and big data perspectives

www.WATTAgNet.com/articles/35960