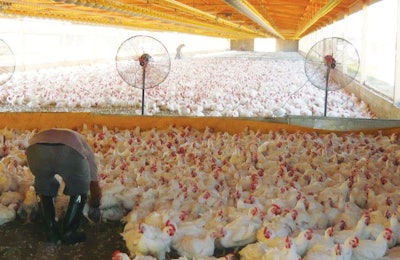

Harvesting broilers prior to slaughter needs to be carried out quickly, but also with care so that birds are not harmed. There are various harvesting methods, but each has its benefits and drawbacks.

While it is widely known that birds should be caught by the body, all too often workers catch birds by the legs, carrying and caging more than one bird at a time so that sending to the processing plant is not delayed. While this may ensure speed, birds may suffer scratches, bruises and bleeds, and this can lead to downgrades at the plant.

Some companies insist that workers handle broilers with greater care. This, however, results in greater costs as more workers are needed, but the number of rejected or downgraded birds will be lower, compensating for the additional harvesting costs.

There are also automatic harvesting processes. These have improved since they were first introduced and the damage done to birds has also been reduced over time. However, this approach has not been widely adopted due to its comparatively high cost, where labor is cheap and abundant.

Any good harvesting method must do as little harm to birds as possible to minimize rejects and downgrades, but capture, caging and loading methods must be quick so as not to interrupt supplies at the plant each day, irrespective of the speed of each worker.

Drawing on elements of the various approaches to harvesting mentioned above, and also on how cage-produced eggs are collected, an alternative method of harvesting birds could be as follows.

Hybrid method

At harvesting time, rather than running empty and filled cages or containers across a network of plastic tubes, an extendable conveyor belt could be installed in the poultry house onto which harvesters directly place each bird that has been individually captured with care.

The house needs to be darkened, and preferably a blue light employed so that birds remain calm while on the conveyor belt. To further ensure that birds do not leave this conveyor belt, a mesh tunnel could be constructed over it.

The belt will be long enough to transport the birds out of the house where they are delivered to a special bin, similar to that used in automatic harvesting systems.

The use of temporary mobile barriers is retained to bring birds together to make catching easier, but where large quantities of birds are to be collected, it may be possible to adapt the front of an automatic harvester, making it easier to direct. This could be used to move birds toward the conveyor, where workers can load them onto the belt for transport out of the house.

Birds would be delivered to workers who would place them into cages or containers, holding them by the body. This caging area needs to be dark, quiet and well ventilated to ensure the comfort of workers and birds alike, and should also be lit using a blue light.

The loading area should be ventilated in a way similar to the way in which the houses are ventilated to stop evaporative heat from rising while birds are being loaded. This area also needs to be shielded from the sun if birds are loaded during the day.

The various steps in this process need to be carefully synchronized to avoid delays in dispatching birds.

Adopting this method of collecting birds would only mean sourcing a small number of relatively low-cost additional elements, many of which could be made in-house. These would include an extendable conveyor belt, a special bin into which birds are unloaded, elevating platform to ensure that cages are within reach of workers for efficient working, and a portable cabin within which to locate the bin and other equipment and from within which the caging team will work.

Additionally, a transporter to raise the filled cages onto the trucks would be needed and, if loading takes place during the day, a shade-creating mesh or awning would also be recommended. Where forklift trucks have been used to load trucks, there is no reason why their use should not continue if this method is adopted.

The various elements of this suggested method of harvesting need to be carefully synchronized, but the approach could offer rapid dispatch of birds without harming broilers. | Eduardo Cervantes Lopez

How preventing wing flapping improves chicken processing