With the tremendous growth in the number and variety of fully-cooked value added products on the market, it is important for processors to maintain optimum safety, quality and yield of products during cooking.

The diversity in poultry products such as batter and breaded, glazed, grilled and roasted requires different cooking processes and ovens that have flexibility to manage temperature, air speed and relative humidity. This allows optimum product quality characteristics such as browning, yield and juiciness.

Achieving endpoint temperature

Regardless of the products being cooked, all must be cooked to an endpoint temperature that is a factor of time and temperature for product safety. Reaching a core endpoint temperature of 71 C ensures product safety. Processors may have higher temperature specifications to make sure that all products reach the desired endpoint.

Two of the most important product characteristics to achieve even cooking are uniformity in portion size and uniformity in core product temperature. Overcooking will reduce the yield and juiciness of the product, so endpoint temperature must be closely monitored to maintain product quality.

Multiple-zone cooking

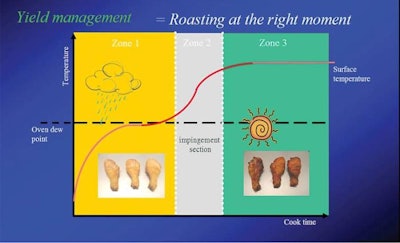

The best way to maximize product yield and decrease cooking time is to increase relative humidity. However, high relative humidity will prevent products from browning or developing roasted appearance. Having ovens with multiple zones where each zone can be individually programmed to control temperature and relative humidity can help processors achieve the desired appearance of the product while managing product yield and juiciness.

Producing injected wings with a roasted appearance, for example, would require a different cooking process than glazed fillets in order to manage the appearance and yield of the products. Best cooking practices for wings with a roasted appearance would be cooking the wings initially with higher humidity to maintain the yield and juiciness and finishing with a zone in the oven having a higher temperature and lower relative humidity which will promote color development (See “Oven with variable cook zones”).

Glazed products would require different cooking parameters. When glazed products are cooked, the cooking process requires setting the glaze in the first zone of the oven with lower relative humidity. High humidity in the first zone of the oven, however, would wash the glaze off. Once the glaze is set, higher humidity can be used in the oven’s second zone to preserve the yield and juiciness of the products.

Partially fried products

Today, many of the fully-cooked, batter-and-breaded products sold at retail are not fully cooked in oil. Instead, they are partially fried for 25-45 seconds at 177-199 C to set the coating and begin to develop some color. Parfried products are not fully cooked after the parfry step.

Fully cooking with air flow, oil

The fully-cooked products sold at retail are generally fully cooked in a spiral or linear oven. One of the most important cooking parameters for batter-and-breaded products to maintain the crispiness of the coating is air flow. The best cooking scenario for coated products would be an oven having both horizontal and vertical air flow with an oven temperature of 200-250 C.

Finishing the cooking of coated products in an oven is advantageous for efficient oil management and reducing the amount of oil needed while also being able to better control product yield and juiciness.

Cooking equipment has greatly improved in recent years, and processors using the right combination of cooking parameters will realize maximum product safety, quality and yield.