A new generation of smart deboning machinery promising to cut labor needs from the intensive process by 50 percent is arriving on the scene. It could shift the way U.S. processors staff and equip their plants.

While the machines may not yet surpass the effectiveness of a human worker, automatic deboning devices are becoming significantly more competitive. Over the past two decades, the machinery made key technical advancements enhancing its efficiency and its potential value to this high-turnover phase of processing.

WATT PoultryUSA surveyed four poultry processing equipment manufacturers - Meyn Food Processing Technology B.V., Marel Stork Poultry Processing B.V., Baader Linco Inc. and Foodmate US Inc. – to assess the current state-of-the-art of deboning technology.

High turnover and a tight labor market

The equipment manufacturers citied two key reasons for greater automation in the poultry plant: increasingly challenging labor markets and steadily advancing technology.

Working in a poultry plant is rigorous and employee turnover is typically high. Deboning is the highest turnover area in the plant and difficult to keep staffed. This, along with a stronger domestic economy and an aggressive federal stance on immigration, makes it more difficult for processors to find the workers they need. At the recent US Poultry & Egg Association 2018 Poultry Processor Workshop, multiple speakers focused on the on-going difficulty of recruiting and retaining workers.

Since the dawn of vertical integration, poultry plants steadily became more automated to increase line speed and bird throughput while reducing labor. Now, the greatest opportunity for further automation lies with deboning of white and dark meat. The manufacturers agreed that automated deboning represents the greatest opportunity for saving labor right now.

Technical advancement

Historically, U.S. processors relied on manual deboning to achieve the highest possible yield and it worked because of a strong labor pool. But, the current conditions may create an ideal situation for processors to switch from manual deboning to automatic.

Now, Baader Linco CEO Oliver Hahn said, the machinery is far more advanced than the devices processors saw 15 or 20 years ago when first considering the technology. He said modern machines are now able to deliver a better yield and higher reliability. Even if labor conditions improved, processors will likely still choose automated deboning.

“The next wave of automation is here to stay,” Hahn said. “Simply because the technology has changed so much. It’s gotten so much better and so much more reliable.”

The technology behind the machines

Today’s machines are able to measure each individual bird, or cut, and then adjust the slicing devices to make the most effective cuts. The first deboning systems were mechanically set to make the same series of cuts on every bird coming down the line. This resulted in inconsistent performance and yield.

Modern systems use a variety of methods to assess the size of the bird and then use software to determine how the machine should be adjusted for the best yield. Hahn said the machines determine a measurement point – the width of the bird or its shoulders, for example – then use an algorithm to figure the bird’s likely skeletal structure. The slicing tools inside the device are then adjusted so the blades are neither cutting into the bone nor leaving too much meat on the carcass. The machines are able to take measurements and adjust the tools for each bird within milliseconds.

One system, the Foodmate ULTIMATE Whole Leg Deboner uses X-ray vision and image analytics software to maximize yield. Paul Breure, Foodmate’s training and development manager, said the device debuted in 2017 and is the first of its kind to use X-ray vision to measure and analyze bone structure. He said the X-ray data is analyzed to get precision measurements and cut for the best yield at the speed of 100 legs per minute.

Along with enhanced capabilities, the machinery is now more durable and reliable than past iterations, Hahn said. They now include more robust electronics and circuitry capable of withstanding the harsh environment of a poultry processing plant.

Labor savings and trade-offs

Automation promises serious labor savings for the deboning process. All four manufacturers agreed an automated deboning line can reduce labor needs by half. Although there are costs and yield trade-offs associated with adopting automation, the equipment makers argue the machines will offer better performance over the long term.

Of course, one must compare the machine’s performance versus a human worker in terms of yield. The companies agree the technology cannot yet match nor surpass the performance of a high-performing deboning crew.

“A machine will never do as good a job as a human will, but it’s consistent,” Larry Campbell, Marel’s vice president of sales for North America, poultry, said. “It comes to work every day (and) does the same work every day, every hour, regardless of the environment.”

Hahn said a skilled worker would likely perform better than the best machine over a short period, but the machine will deliver comparable and more consistent yield over the long term without the need for constant replacement and retraining of workers.

Another stumbling point for automation is quality control. Some companies offer automated visioning solutions that can detect quality issues with birds, but it’s important to remember deboning machines cannot detect product quality like a human worker can. If a carcass with quality issues – for instance a bird missing a wing or with some kind of internal damage – enters the machine, it can result in lower quality or damaged product coming out of the machine which requires rework.

A hybrid approach?

Plant operators and processors who are hesitant to adopt full automation for whatever reason may also consider adopting a hybrid system which combines elements of manual and automatic deboning.

Simon Langhorn, a key account manager for Marel, said some of his customers are opting for a hybrid approach of splitting deboning between mechanical and manual. This way, operators are able to save on machinery costs and maintain a higher yield than a fully mechanical operation. Additionally, they can avoid staffing problems by assigning the machinery a percentage of the work. This could be the difference between running the plant five days a week versus six or seven, which can help retain workers who otherwise couldn’t work those extra hours.

The market reception so far

Despite reservations processors may have about the potentially lower yield of automated deboning, the realities of the labor market and technical evolution are driving up interest in automation. The manufacturers who commented on the market said their customers are consistently concerned with labor and what steps can be taken to reduce the need for manpower. They said automated deboning systems are selling in the U.S.

Langhorn said in his experience the market for automated deboning picked up considerably over the past two years. Some customers are going for a fully automated line while others are adopting the hybrid approach. Nevertheless, he said the vast majority of processors are still using manual deboning lines. But, the larger market trends will likely keep pushing processors toward automation.

“It’s going to be a situation where we’ve got to automate everything. The more automation we can come up with and develop its going to be better for our customers,” Langhorn said. “Europe is almost 100 percent mechanical debone … because they just can’t get the labor. I think eventually the US will go that way too. It may take five years, it may be 10 years but it’s definitely trending in that direction.”

Reviewing a range of deboning machines available

Automated deboning machines made great strides in the past two decades and are now capable of reducing deboning labor needs by 50 percent. Four leading processing equipment manufacturers shared information about their products.

Baader Linco

Machines: BA656 Breast Deboner, BA632 Thigh Filleting System

How they work: The BA656 processes front halves, with or without wings attached. It automatically measures front halves and uses those measurements to regulate the cutting and scraping tools. The machine can process front halves ranging from 600 to 2400 grams (1.3 pounds to 5.3 pounds). It can run at 85 or 100 front halves per minute or 50 front halves per minute with wings on.

The BA632 is part of Baader’s ProFlex Cut Up line system. The Cut-Up line determines bird size for sorting and processing. The machine uses a series of blades to cut the meat from the bone, then automatically extracts meat by cutting it and pulling it off the bones. It can produce 230 thighs per minute and can process saddles from birds greater than 11 pounds live weight.

Labor savings: The BA656 can reduce the labor needs of a deboning line operating at 70 front halves per minute for tender-out production by about 45 percent. The BA632 uses 7 workers to process 115 birds per minute. The company said this is a more than 50 percent labor saving over the machinery of its nearest competitor.

Foodmate

Machines: For dark meat: ULTIMATE Whole Leg Deboner, OPTI-LTD Whole Leg Deboner, OPTI Thigh Deboner with KCS, OPTI Drum Deboner and FM6.50. For white meat: Maxima, Max 6000, Maxima LT, FM 7.50.

How they work: Paul Breure, Foodmate’s training and development manager, said the ULTIMATE Whole Leg Deboner is the first in the industry to use an X-ray measurement system. The X-ray system precisely measures each leg and uses the data from the scan to automatically adjust the machine for each leg at the speed of 100 legs per minute.

“The X-ray allows the machine to cut with surgical precision around the knee joint, leaving the kneecap attached to the bone ensuring very high yields and minimum labor during trimming,” Breure said.

In general, he said, Foodmate’s machines are capable of handling size variations, and when necessary its machines can handle larger birds using adjusted size shackles.

Labor savings: Foodmate estimates deboning automation can save labor by an average of 50 percent.

Marel

Machines: FHF-XB front half deboning system and AMF-I breast cap filleting system

How they work: Simon Langhorn, a key account manager for Marel, said the machines are designed to automate key positions which are especially high turnover while keeping yields high. Front halves or caps are sized to a certain weight range and then manually loaded onto the machines. The FHF is made for full automatic deboning of “football” birds and front halves and the AMF is made for deboning caps, or the breast shell with the back removed. Both machines make the cuts and pull the breast meat off the bone automatically and then the breast meat and tender are harvested by hand. The AMF-I features a mechanical trigger which determines the size of the cap automatically, the machine is then able to adjust itself for bird variance based on the trigger system.

Labor savings: Langhorn said the machines can reduce deboning line labor needs by about 50 percent.

Meyn

Machines: Meyn Rapid breast deboner M4.1, Meyn WLD Whole leg deboning M3.0, Meyn TDS Thigh deboning solution M1.0

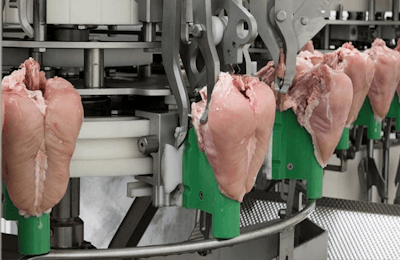

How they work: Jeroen Bohm, product manager at Meyn, said the company’s deboning machines are designed to handle a wide weight variation within a single setting without the need for individual bird adjustment. The company’s deboning products use a unique carousel design – a round module where a carcass enters one side and exits the other finished – to work more quickly and effectively. He said pre-deboning sorting and weighting is recommended to achieve the optimum performance and the company offers automatic sorting products, assessing both weight and product quality, as part of its cut-up solutions. The machinery’s processing capacities are: 117 birds per minute for the Rapid breast deboner M4.1; 70 legs per minute for the WLD whole leg deboning M3.0 and 120 thighs per minute for the TDS Thigh deboning solution M1.0.

Labor savings: Labor savings range depending on the product. Meyn estimated the Rapid breast deboner M4.1 saves 33 full time equivalent employees (FTE); WLD whole leg deboning M3.0 saves 24 FTE and the TDS Thigh deboning solution saves 7 FTE.