Making quality job one may have become a bit of a cliché in the business world, but it's still a motto that rings true for the Cargill Animal Nutrition plant at Seguin, Texas.

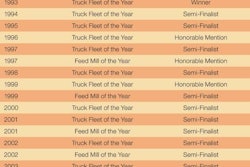

The plant was named runner-up in the 23rd annual Feed Mill of the Year competition. The American Feed Industry Association (AFIA) and Feed Management co-sponsor the Feed Mill of the Year Award. The annual Feed Mill of the Year contest is designed to identify excellence in feed mill operation, including factors relating to efficiency, safety and biosecurity. Feed mills taking part in the competition receive direct feedback from AFIA to assist them in improving their performance, not only to improve their future competencies as they relate to the contest, but even more importantly, to help them improve overall facility operations.

The Feed Mill of the Year program underwent a redesign process in 2007 which incorporated a new grading system to provide benchmarking feedback' to every plant that entered the competition.

Quality is focus

Serving an evolving marketplace deep in the heart of Texas, about 40 miles northeast of San Antonio, Texas, the Cargill plant at Seguin has a commitment to excellence that is evident everywhere from its employee relations to its quality control of products and services to its dedication to customers.

"We believe quality is one big thing," explains Plant Manager Paul Yandle in explaining how the facility focuses on achieving excellence, whether relating to employees or relating to customers. Yandle is assisted in the task of ensuring a quality operation by his management team:

Both Yandle and Trout are quick to recognize the contributions of all the other members of the management team in helping the mill achieve its level of excellence. They also note they are appreciative of the hard work and leadership shown by Abrameit, Thornton, Jackson and Waxler in helping the mill achieve its Feed Mill of the Year distinction. A total of 46 employees, including 35 working in production, four in administration and seven in sales, provide the workforce for the plant. Output averages about 120,000 tons of feed per year, although Yandle says they are currently in the process of an expansion to take the capacity to 155,000 tons per year.

The facility was built for the Anderson Clayton Company in 1972 by Todd and Sargent. It was later purchased by Cargill, Inc. in 1987. The plant runs a diverse operation with a production mix that includes 38 percent bulk feed and 62 percent packaged product. About 66 percent of feed going out the door is pelleted and 24 percent textured. Yandle describes the plant's current business as focusing on service to the retail farm store marketplace with key market segments of show feeds and supplements, deer and wildlife feeds, equine products and beef feeds. "Business is built on value-added brands, like Sportsman's Choice Record Rack, ACCO Showmaster, Safe and Sound, ACCO SuperCharged, Paymaster, Southwest Competitor, and Right Now Mineral," adds Yandle.

While the markets have changed, the Cargill plant at Seguin has changed as well so that it is in better position to meet those differing market demands. Over the years, it's become more focused on value-added brands and deer and game feeds. To help meet the varied needs of its new market segments, the mill installed a Repete controlled in-line textured system, and utilizes bulk screening capabilities, bag screen capabilities for multiple product forms, robot palletizing, and the capabilities of a Repete short mix system in getting the job done. It is the Repete short mix System and Repete controlled textured blending system, along with its TagMaster on-demand tag printing, that Yandle identifies as having the greatest impact on the plant's operations.

Along with ensuring the plant has the technological capability to meet changing markets, the folks at Cargill's Seguin facility are also pinpointing ways to improve the efficiency of feed manufacture. "To monitor efficiencies, we use Cargill's Model Mill program which monitors and reports daily crewing needs and efficiencies for each process based on the product mix for that day," adds Yandle. The Model Mill program utilized by the plant is a computer model based on a continuous improvement program utilized by Cargill Animal Nutrition over the past 25 years. According to Cargill, its own Cargill feed plants, as well as many other mills worldwide, make use of the program which supports plant management by modeling processes of a feed manufacturing plant, including product quality, economic optimization and operational efficiency. It allows plant managers to make comparisons with a pre-defined standard and work toward world class operational efficiency via a 12-step process. The program calculates the expected cost of manufacturing, given the engineering limitations and product mix parameters. This degree of customization enables comparison of the model's standards to actual plant costs, labor and efficiencies.

In another effort to meet its quest to measure up, the plant follows programs that keep quality at the forefront in all aspects of its operation, from employees to customers. "We address quality through our Q3 program, which focuses on product consistency and quality service," explains Yandle. "We believe quality has three components: quality people, quality products and services, and quality customers."

Employee recognition

Dedication to quality employee relations can be traced to a program Yandle calls Pillars.' The program can be used to recognize employees for outstanding behaviors. "Pillars are awards to employees based on one of the following categories: performance, innovation, leadership, learning, alignment, results, and service and quality," Yandle says. "A committee with employees from each of the South Texas District branches meets on conference call monthly to recognize employees and award Pillars cash awards."

He says the plant's safety program is self-directed by the production employees. Every year a safety committee is appointed to manage the safety program. "This committee has a budget and is provided the resources to make any necessary safety improvements to the facility," he explains. "We also conduct monthly audits looking for defects in the area of safety and loss control."

Yandle says the plant has also changed its production employees benefit structure to what is called 1-Plan, 1-Team. "Our production employees now receive the same salaried benefit structure as our management team. Monthly meetings are held with all employees to review our current financial results and business performance," Yandle says. "Our focus on safety also improves engagement. Our employees care about each other and their welfare."

.jpg?auto=format%2Ccompress&crop=faces&fit=crop&h=48&q=70&w=48)

.jpg?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)

.jpg?auto=format%2Ccompress&fit=crop&h=167&q=70&w=250)