Foodservice accounts have become one of the broiler industry's major outlets for breast meat. Sales of whole-muscle items such as nuggets, strips and sandwich portions have helped fuel the growth in deboning. Faster growing birds and the pounds per man hour and yield advantages of processing larger birds have led to processors pushing up weights of birds raised for deboning. Just 10 years ago, a 6.5-pound live weight broiler was considered a "big bird," but now, the target live weight for many "big bird" plants is 8 pounds and higher.

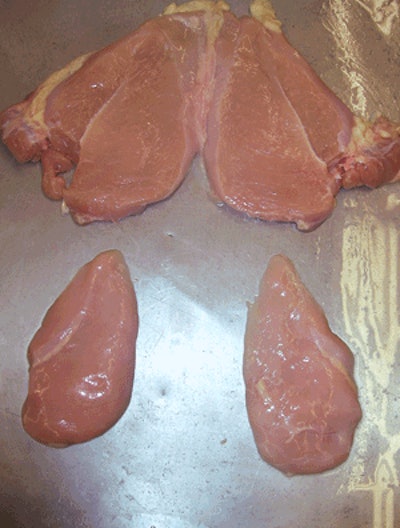

Larger birds mean bigger breast meat butterflies, filets and tenders. On average, an 8-pound live weight bird will provide a breast butterfly that weighs just over 1.5 pounds. Now, even some products like "chicken tenders" sold in restaurants are actually tender pieces cut from the roughly 5 ounce tenders that come off an 8 pound bird. Processors are doing more slicing, slitting, cubing and cutting of raw poultry meat then ever before.

Sizing and cutting

Many whole-muscle, single-piece foodservice breast meat products need to be made within tight specifications for length, width, thickness and weight. These specifications have been designed to ensure things like uniform cooking times, proper bun coverage and portion control. Poultry processors really only have three options for making these sized single-piece whole-muscle products: hand sizing and cutting, volumetric sizing and mechanical cutting, and vision system sizing and mechanical cutting.

Hand sizing and cutting is still the primary method of producing portion control pieces of breast meat items at some USA broiler plants and in many plants in other countries. People working with scales and either knives or scissors cut pieces of meat to fit customer specifications. In these plants, dozens or even hundreds of individuals can be occupied with producing portions for sandwiches and other products. Because of the relatively small size of the finished portions, usually 3 to 5 ounces each, the labor cost of manually producing these sandwich portions is high, even in what used to be considered low wage countries like Brazil. Many USA plants now reserve hand portioning only for pieces of meat leftover after a mechanical process has cut a portion or portions from that piece.

Volumetric portioning

The concept behind volumetric portioning is relatively simple; meat is drawn or pushed into a mold which is sized to hold the desired amount of meat and the meat outside of the mold is cut off. This volumetric process has been patented by Tyson Foods, Inc., in the USA and Marel Food Systems has licensed this patent. Marel produces the TSM Profiler, which is employed by several processors in the USA.

Larry Campbell, poultry division vice president, Marel Food Systems, described the typical application of volumetric portioning in a broiler plant. In many cases, the process starts with sizing the front halves of the birds, according to Campbell. Plants that employ automatic breast deboning systems will always size the front halves before deboning and some plants that use manual cone lines will also size before deboning.

Separating the front halves by weight range improves the performance of the automatic deboners and narrows the size range of the breast meat pieces coming off the deboning line. Campbell said that plants that don't size prior to deboning will generally size and sort the breast meat after deboning.

Breast filets or butterflies can be flattened prior to portioning. Flattening reduces the thickness of the meat and can allow for more portions to be cut from one piece.

Next, the breast meat will go to the volumetric portioner. Portioners can be fitted with molds to size portions either from breast butterflies or from filets. Campbell said that some plants will run a butterfly through a volumetric portioner to get two sandwich portions and then run the leftover meat to a hand line to get breakfast sandwich size portions, nuggets or strips. Other processors will run the leftover meat through a second TSM machine to get another portion and then send what is left to a hand portion line to get more out of the piece. If a butterfly weighs 28 ounces and the sandwich portions are 5 ounces, there is the opportunity for a lot of trim if the processor isn't clever with portioning; each piece is a jigsaw puzzle. Weighing and sorting after each step can help the processor maximize return on portioning.

Leftover meat after portioning can be used in formed products, such as IQF breast meat or sold to another processor as trim. Trim sells for a lower price than whole pieces of breast meat, so the idea is to get as many portions as possible while making as little trim as you can. The processors product mix to all its customers can play a siginificant role in how well smaller pieces of meat can be utilized and this in turn affects overall return on portioning.

Prime Equipment Group manufactures the PS-8 volumetric portioner which is currently available only outside the USA. This machine can portion either skin-on or skinless product, and it can portion meat with either the bone side or skin side of the meat in the mold. After the meat is forced into the mold, a reciprocating blade is used to cut off the excess meat.

Vision system portioning

DSI Accura water jet portioners, manufactured by FMC Foodtech, use a vision system and an onboard computer to scan and analyze each piece of meat entering the machine. The vision system provides data on the size and shape of the piece of meat and the computer calculates which cuts should be made to optimize the return from that piece of meat. Product specifications stored in the computer are used to guide the high-pressure water jets to make the cuts.

A combination of products can be made out of each piece of meat in one pass through the machine, rather than using multiple machines or a combination of a machine and a hand line as might be the case with volumetric portioning. One disadvantage of this technology is the high capital cost; volumetric portioners are significantly less expensive.

Some processors employ horizontal slicers before the meat is portioned in the DSI, particularly for large filets or butterflies. Making the horizontal slice produces a piece of uniform thickness for portioning and the top piece can be portioned to make other products. Equimex HS 1000 series horizontal slicers can both cut and remove this top slice of meat.

Other options for size reduction

Not all portioned whole muscle products have tight three dimensional or weight specifications. Some products that are diced or stripped can be cut from either natural breast pieces or from trim without generating excessive scrap.

Peter Johnson, general manager, Carruthers Equipment Company, said that ethnic food restaurants present an opportunity for processors to provide sliced meat, particularly thigh meat. He said that Carruthers machines are used in commissaries of some Chinese food restaurant chains to slice and dice thigh meat and some breast meat so it is ready-to-cook upon arrival at the individual restaurants. Processors could offer this service for both Chinese and Mexican cuisine. Turkey meat, partucularly thigh meat, also has portioning potential for these applications.

Some processors are portioning large chicken tenders into two or three pieces for foodservice sale. Prime Equipment Company's PC-4 portioner can be used to portion tenders into equal naturally shaped pieces.

The PC4 portion cutter can cut thigh meat, tenders and filets. It uses a mold with crevices or guides where the knife blades pass through to cut the meat. The mold is washed out with water after each cycle so there is no build-up in the crevices. This machine can be used to produce strips, cubes or portioning.

Peter Makert, Equimex, commented on demand for portioned pre-cut raw poultry meat, even for retail sale, in Europe. "In Europe slicing is going sky high with birds getting bigger and fillets really needing to be sliced," he said. Demand in the U.S. for these types of poultry meat products is not as high, perhaps, because U.S. consumers tend to eat more meat per serving.

Some foodservice applications call for whole-muscle breast meat, but if the end product is batter breaded and sold IQF, the product can be a multiple-piece, portioned product. Stork Food Systems, which is now part of Marel, has the RevoPortioner which can form whole-muscle, multiple piece shapes from breast meat filets. This machine can portion whole muscle meat into many natural shapes, including three-dimensional products, while maintaining consistent size and weight.

Portioning will continue to grow in significance to poultry processors as bird sizes continue to increase and sales of strips, nuggets and sandwich size portions grow. Processors will need portioning equipment that provides the best utilization of their meat mix and labor resources while meeting customer specifications.