1. How much time should be spent cleaning pig pens?

Cleaning of rooms or whole houses on pig units has become more frequent with the widespread adoption of all-in/all-out practices. This in turn has directed attention to the labour aspects of the clean-up process. From research, a considerable amount of working time can be wasted by failing to pre-soak the pens or not using soap to take care of difficult residues on floors and walls.

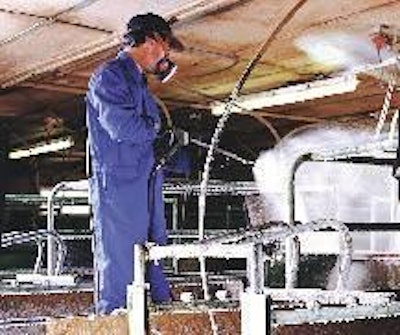

An examination by Dr Dan Hurnik at the Atlantic Veterinary College of University of Prince Edward Island in Canada has demonstrated how the procedure followed can cut pig pen cleaning times in half when compared with a simple wash-down using cold water. His study took 20 pens that were being cleaned to receive the next batch of feeder pigs. Each fully-slatted pen measured some 6.7m long and 2.7m wide (22 feet x 9 feet) and contained a single wet/dry feeder with 2 feeding places. The number of minutes needed to complete the cleaning was compared according to whether or not there had been a pre-soak and using cold or hot water with or without soap.

"Cleaning is of critical importance as no disinfectant will work in an unwashed barn," Dr Hurnik noted in his study report. "Hot-water pressure washers offer the use of hot water for washing which has the potential of cleaning more efficiently, however they are more expensive and require more energy and maintenance. Pre-soaking the pens is used by some producers to help with the washing process. The use of soap is suggested because it breaks down the biofilm and waxy residues which water alone will not remove. Soap acts like a degreaser, helping to dissolve the biofilm that can protect bacteria and viruses from washing and disinfection."

Using only cold water without soap or pre-soaking, he reported, the wash time averaged over an hour per pen. Hot water cut this by about 22% (see Table). While hot water was more comfortable to apply, said Dr Hurnik, it created a fog that affected working conditions by making it harder for the operator to see. Soap with cold water brought a time reduction of 8 minutes per pen or about 12% and soap with hot water reduced the original time by almost one-third.

Spraying the pens to pre-soak them and so loosen manure before bringing in the pressure-washer was even more influential on the time. In cold-water routines this pre-soaking appeared to cut the washing time by almost 50%. But Dr Hurnik also points out that the results showed identical times for both hot and cold water where pre-soaking and soap were applied.

A further part of the study had involved measuring the growth rate of pigs from entry to the cleaned pens at 25kg until marketing at 110kg. On average the animals reached market weight in slightly more than 98 days when coming from accommodation that had been washed without water alone. This compared with under 96 days for a wash-down with soap and cold water and under 93 days for using soap and a disinfectant with cold water. Notably, however, no extra effect on weight gains was seen from the use of hot water.

2. How much water is needed to clean pig pens?

Giving a pre-soak to pens before pressure-washing them offers several benefits, an advisory bulletin from Irish agricultural development agency Teagasc has observed, not least by reducing the amount of labour time required for cleaning between batches. The pre-soaking also fits work routines because it can run unsupervised during the night. In addition it should mean less water being used for the actual washing process so that less slurry is produced.

In response to the charge that pre-soaking could increase the total quantity of water used for cleaning pens, the advisers said the volumes used for the preliminary soak were likely to be relatively small. By fitting a timer, the pre-soak spray system could be arranged to work intermittently such as in a sequence of 5 minutes on and 20 minutes off.

Advice in France has been to follow a cycle of 5 minutes of operation repeated every 15 minutes for at least 4 hours, to ensure enough penetration of the organic material on pen surfaces. The French recommendation is also to begin pre-soaking within 3-4 hours of the pigs' departure and to aim to spray all surfaces with the equivalent of 1.5 litres of water per square metre.

As the Irish bulletin notes, detailed measurements made in France at the then ITP pig institute (now IFIP) have indicated that pre-soaking used 17 400 litres of water per year for the grow-finish pens, another 12 600 litres annually for the farrowing pens and 9700 litres/year for the nursery on a typical French farrow-to-finish unit of 140 sows. These amounts contributed to a water use totaling some 133 100 litres (grow-finish), 96 900 litres (maternity) and 57 200 litres (nursery) when all phases of the cleaning route were included. Out of the 287 200 litres per year (or 2000 litres per sow) used by the unit to clean its houses, therefore, some 46% of the usage was for grow-finish and 34% for farrowing while 20% was for the weaner accommodation. A total of 164 000 litres went into the basic task of washing the room.

The figures were compiled from measurements on a test site that batch-farrowed every 3 weeks and weaned at 28 days. The 2 farrowing rooms were cleaned between batches, so every 6 weeks. Cleaning took place at intervals of 8-9 weeks in nursery rooms and 14-15 weeks in finishing. The records also showed a calculation of the total square metres of floor area for washing per year in each of the sections. From this, the quantity of water to wash one square metre in the finishing house amounted to 47 litres. In farrowing places it was 51 litres and in the nursery just under 40 litres.

The Irish bulletin also points to a separate measurement by the team in France that of the time spent in cleaning these pens. It was reckoned to total 253.4 hours per year for the complete 140-sow unit, with 49% of that taken up by cleaning the grow-finish pens. Another 31% went into farrowing clean-up and 20% to cleaning the nursery between batches. But perhaps the most interesting aspect, commented the advisers in Ireland, came when the time expenditure was re-calculated on the basis of per square metre so it could then be compared with water usage. Since the amount of time involved in cleaning on this unit was shown to be just under one hour per square metre of housing, it meant an average of 19 litres of water used per minute.