Pad cooling is called a simple yet effective way of reducing the inside temperature of a pig-house, even in places where the outdoor climate is humid as well as hot. The principle behind the method is the known one of using warmth to evaporate droplets of water. In this case the evaporation removes heat from the air passing through the honeycomb surfaces of a wet-cell pad.

Simplicity is also behind most installations for this style of cooling. The pad itself will be placed across the end wall or a side section of the house while extractor fans at the opposite end draw air through the building. To keep the cells wet, water from a small tank is pumped to the top of the pad and either allowed to trickle down by gravity or misted by nozzles. The water then is collected ready for recirculating as part of a mixture with a fresh supply.

Inevitably, the pores of the pad can become clogged with dust while the water may turn green with algal growth. Regular cleaning of pads is therefore an essential part of good operation and some users add an inhibitor such as copper sulphate to the water to limit the algae. In fact the ability of a wet-pad to trap dust at the air inlets is considered a real benefit in some countries because the material might otherwise have carried pathogens into the house. Pads have even been advised in Asia as a specific strategy for units troubled by the PRRS virus.

Also seen in an Asian setting is that pads are sometimes installed with a covering of plastic mesh. This may be to keep out insects, as in the example from a gestation house in the Philippines shown in an accompanying photo. The same unit provides a further instance of cell craft, this time in relation to farrowing facilities.

New places had been needed for a 1000-sow extension of an existing 700-sow farm. An order was placed for Betco buildings equipped with fans and cooling pads from the Automated Production Systems company of GSI. The plan included the extra farrowing structure pictured, in which 5 rooms would each have 44 pens. These pens are arranged in 4 rows of 11 places each. But the positioning of the rows was judged carefully in order to have a reasonable temperature for the sows without creating draught conditions for the piglets.

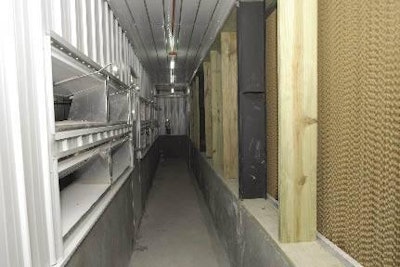

Tunnel ventilation was ruled out for the farrowing rooms on the basis that the through-speed of the air would be too high. So the inlets chosen are for cross-ventilation. Moreover, they do not open directly onto the exterior. The third photo shows that they are instead separated from the wet-cell pads by a narrow corridor.

It is a passageway with a purpose. This so-called tempering area is about a metre wide. Fresh air must cross it after being cooled by the pads, before lifting to the inlets for entry into the room holding sows and litters. The designers insist it is a cost-effective and practical solution to avoiding the risk that cooled air from a wet-pad could drop down to the baby pigs in the first pens and chill them.PIGI